Boiler Tube

ASTM A179 Seamless Steel Tubes

ASTM A179 Finned Tube is a heat exchange element. In order to improve the heat exchange efficiency, fins are usually added to the surface of the ASTM A179 seamless heat exchange tube to increase the outer surface area (or inner surface area) of the heat exchange tube, so as to achieve the purpose of improving the heat exchange efficiency.

ASTM A179,ASME SA179 steel tubes covers minimum-wall-thickness, seamless cold-drawn low-carbon steel tubes for tubular heat exchangers, condensers, and similar heat transfer apparatus.ASTM A179,ASME SA179 covers tubes 1/8 to 3 in. [3.2 to 76.2 mm], inclusive, in outside diameter.

Types of ASTM A179 Finned Tube for Heat Exchanger

ASTM A179 L Type Finned Tube,

ASTM A179 LL Type Finned Tube,

ASTM A179 KL Type Finned Tube,

ASTM A179 G Type Finned Tube,

ASTM A179 H Type Finned Tube,

ASTM A179 Extruded Type Finned Tube,

ASTM A179 HF Finned Tube,

ASTM A179 Elliptical Finned Tube,

ASTM A179 Stud Finned Tube,

ASTM A179 Serrated Finned Tube,

ASTM A179 U Bending Low Finned Tube,

ASTM A179 Crimped Finned Tube,

ASTM A179 Inner Grooved Finned Tube,

ASTM A179 Longitudinal Finned Tube, etc.

ASTM A179 Finned Tube for Heat Exchanger Quick Details:

Core tube:ASTM A179,ASME SA179 cold-drawn seamless steel tube

Fin type: Solid plain

Fin Tube Type:L Type,LL Type,KL Type,G Type ,H Type ,Extruded Type ,HF,Elliptical Finned Tube,Stud Finned Tube,Serrated Finned Tube,U Bending ,Crimped Finned Tube,Inner Grooved Finned Tube,Longitudinal Finned Tube,etc.

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

Fin thickness: 0.4mm~2mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Customize ASTM A179 Finned Tube for Heat Exchanger according to your drawings

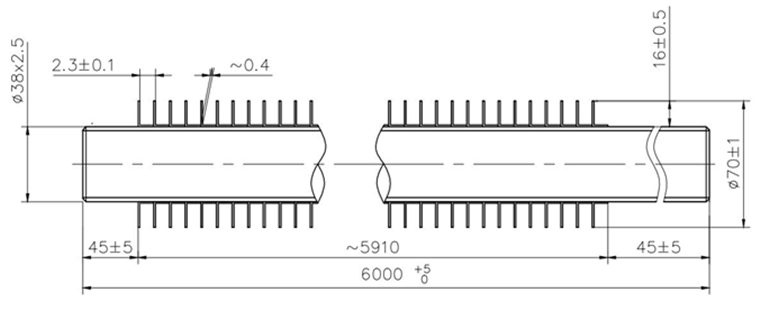

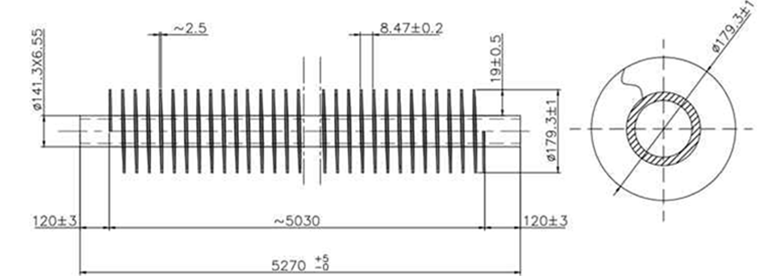

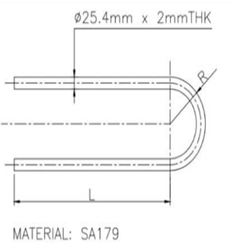

Example 1:

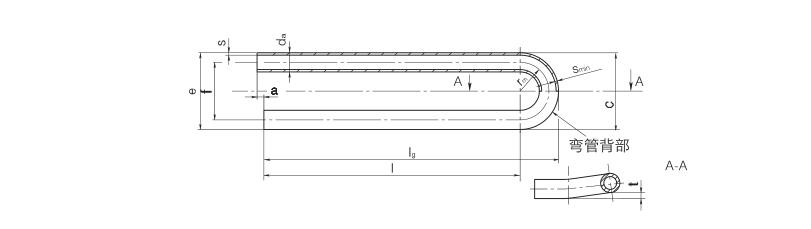

Example 2:

ASTM A179,ASME SA179 cold-drawn seamless steel tube Chemical Composition

| Material | Chemical Composition(%) | ||||

| C | Si | Mn | P | S | |

| ASTM A179 | 0.06-0.18 | ≤ 0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 |

ASTM A179,ASME SA179 cold-drawn seamless steel tube Mechanical Propertie

| Grade | ASTM A179 |

| Tensile Strength(MPa) | ≥325 |

| Yield Strength(MPa) | ≥180 |

| Elongation,% | ≥35 |

| Hardness, HRB | ≤72 |

Manufacturing Process of ASTM A179 Finned Tube

Fin strips (usually aluminum and copper) are folded into an L shape and wound under tension on the surface of the base tube. The feet of the fins are connected together and cover the surface of the fins.

ASTM A179 Finned Tube is combined with two different materials

Core tube material: A179

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Manufacture:Seamless process ,cold drawn.

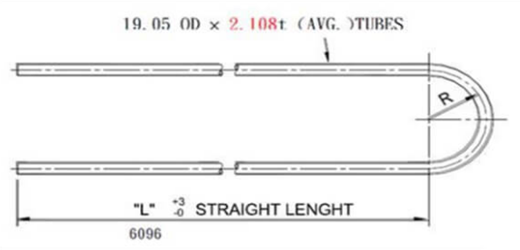

Bending Details: According to Bending Drawings.

Wall thickness(WT): 1.65 mm——2.77 mm.

Outer diameter (OD): 19.05mm – 38.1mm

Length: 6M or specified length as required, the longest is 26 meters.

Ends: Plain End

Chemical Composition of ASTM A179/ASME SA179 U Bend (U Bent) Heat Exchanger Tubes

| Material | Chemical Composition(%) | ||||

| C | Si | Mn | P | S | |

| STM A179/ASME SA179 | 0.06-0.18 | ≤ 0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 |

Mechanical Propertie of ASTM A179/ASME SA179 U Bend (U Bent) Heat Exchanger Tubes

| Grade | ASTM A179 |

| Tensile Strength(MPa) | ≥325 |

| Yield Strength(MPa) | ≥180 |

| Elongation,% | ≥35 |

| Hardness, HRB | ≤72 |

Specifications of ASTM A179/ASME SA179 U Bend Heat Exchanger Tubes

Bending Details: Can Accord to Bending Drawings.

Technical Parameters

Outer diameter: 12.7-38 mm

The bending radius is from 1.5 times the outer diameter to 1250 mm. The outer diameter is over 28mm,

The minimum bend radius can be further discussed.

Straight pipe length is the shortest 1000mm

Straight pipe length up to 12000mm

The bending radius is below 1000mm and heat treatment is required.

Bent pipe technology standard

Technical Standard 7-2-1179

DIN 2879, TEMA RCB 2.31

Can be specified according to customer requirements. Can also follow some general techniques

Specifications.

Heat treatment

If requested by the customer, we add a straight pipe section with a minimum of 150mm according to the elbow.

Heat treatment is performed.

The computer controls the heat treatment furnace and records all the data.

The tube is filled with a protective gas – argon.

Annealing Status:

Annealing | ||

| Solution annealing | Stress relief annealing | Stabilized annealing |

Hydrostatictest

All U-tubes are subjected to a hydrostatic test after heat treatment.

The test time is not less than 5 seconds at the set pressure.

All tubes were blown dry and carefully cleaned after the test.

Measuring, cutting, deburring, cleaning

Accurately measure U-tubes according to relevant standards or customer requirements.

All pipes should be cut to length, deburred, and air dried to the inner wall.

Seal the ends with a plastic cap before packing.

ASTM A179,ASME SA179 steel tubes covers minimum-wall-thickness, seamless cold-drawn low-carbon steel tubes for tubular heat exchangers, condensers, and similar heat transfer apparatus.

ASTM A179/ASME SA179 covers tubes 1/8 to 3 in. [3.2 to 76.2 mm], inclusive, in outside diameter.

Manufacture:Seamless process ,cold drawn.

Wall thickness(WT): 2.0 mm——12.7 mm.

Outer diameter (OD): 12.7mm——76.2 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Threaded

ASTM A179,ASME SA179 Seamless Tube Specification:

| OD (mm) | Wall Thickness(mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

Manufacture

ASTM A179,ASME SA179 steel tubes are made by the seamless process and shall be cold drawn.

Heat Treatment of ASTM A179,ASME SA179

ASTM A179,ASME SA179 steel tubes are heat treated after the final cold draw pass at a temperature of 1200°F [650°C] or higher.

Chemical Composition of ASTM A179,ASME SA179 Seamless Heat-Exchanger and Condenser Tubes

| Material | Chemical Composition(%) | ||||

| C | Si | Mn | P | S | |

| ASTM A179 | 0.06-0.18 | ≤ 0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 |

Mechanical Propertie of ASTM A179,ASME SA179 Seamless Heat-Exchanger and Condenser Tubes

| Grade | ASTM A179 |

| Tensile Strength(MPa) | ≥325 |

| Yield Strength(MPa) | ≥180 |

| Elongation,% | ≥35 |

| Hardness, HRB | ≤72 |

Note —Tubing smaller in outside diameter and having a thinner wall than indicated in this specification is available. Mechanical property requirements do not apply to tubing smaller than 1/8 in. [3.2 mm] in outside diameter or with a wall thickness under 0.015 in. [0.4 mm].

The dimensional tolerances of ASTM A179,ASME SA179 Seamless Heat-Exchanger and Condenser Tubes

Tolerances of Wall Thickness

| Outside Diameter, in. [mm] | Wall Thickness, % | |||||||

| 0.095[2.4] and Under | Over 0.095 to 0.150 [2.4 to 3.8], incl | Over 0.150 to 0.180 [3.8 to 4.6], incl | Over 0.180,[4.6] | |||||

| Over | Under | Over | Under | Over | Under | Over | Under | |

| Seamless, Cold-Finished Tubes | ||||||||

| Over | Under | |||||||

| 1 1 ⁄ 2 [38.1] and under | 20 | 0 | ||||||

| Over 1 1 ⁄ 2 [38.1] | 22 | 0 | ||||||

Tolerances of Outside Diameter

| Outside Diameter,in. [mm] | Permissible Variations, in. [mm] | |

| Over | Under | |

| Under 1 [25.4] | 0.004 [0.1] | 0.004 [0.1] |

| 1 to 1 1 ⁄ 2 [25.4 to 38.1], incl | 0.006 [0.15] | 0.006 [0.15] |

| Over 1 1 ⁄ 2 to 2 [38.1 to 50.8], excl | 0.008 [0.2] | 0.008 [0.2] |

| 2 to 2 1 ⁄ 2 [50.8 to 63.5], excl | 0.010 [0.25] | 0.010 [0.25] |

| 2 1 ⁄ 2 to 3 [63.5 to 76.2], excl | 0.012 [0.3] | 0.012 [0.3] |

| 3 to 4 [76.2 to 101.6], incl | 0.015 [0.38] | 0.015 [0.38] |

| Over 4 to 7 1 ⁄ 2 [101.6 to 190.5], incl | 0.015 [0.38] | 0.025 [0.64] |

| Over 7 1 ⁄ 2 to 9 [190.5 to 228.6], incl | 0.015 [0.38] | 0.045 [1.14] |

Tolerances of Length

| Method of Manufacture | Outside Diameter, in. [mm] | Cut Length,in. [mm] | |

| Over | Under | ||

| Seamless, cold-finished | Under 2 [50.8] | 1 ⁄ 8 [3] | 0 [0] |

| 2 [50.8] and over | 3 ⁄ 16 [5] | 0 [0] | |

| 2 [50.8] and over | 3 ⁄ 16 [5] | 0 [0] | |

Mechanical Tests Required

(1)Flattening Test—One flattening test shall be made on specimens from each of two tubes from each lot or fraction thereof.

(2)Flaring Test—One flaring test shall be made on speci- mens from each of two tubes from each lot or fraction thereof.

(3) Flange Test—When specified as a substitute for the flaring test, for tubes having a wall thickness (actual mean wall) less than 10 % of the outside diameter, one test shall be made on specimens from each of two tubes

(4)Hardness Test—Rockwell hardness tests shall be made on specimens from two tubes from each lot.

(5) Hydrostatic Test—Each tube shall be subjected to the hydrostatic test, or a nondestructive electric test

Surface Condition

Finished tubes shall be free of scale. A slight amount of oxidation will not be considered as scale.