Flange

Flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal.

Offering a reliable way to connect pipe systems with the various equipment, valves, and other components of virtually any processing system, flanges are the second most used joining method after welding.

Using flanges adds flexibility when maintaining piping systems by allowing for easier disassembly and improved access to system components.

A typical flanged connection is comprised of three parts:

- Pipe Flanges

- Gasket

- Bolting

In most cases, there are specific gasket and bolting materials made from the same, or approved materials as the piping components you wish to connect. Stainless Steel flanges are some of the most common. However, flanges are available in a wide range of materials so matching them with your needs is essential.

Other common flange materials include Monel, Inconel, Chrome Moly, and many others depending on the application.

The best option for your needs will depend on both the system in which you intend to use the flange and your specific requirements.

Materials for Flanges

Pipe flanges are manufactured in all the different materials like stainless steel, cast iron, aluminium, brass, bronze, plastic etc. but the most used material is forged carbon steel and have machined surfaces.

In addition, flanges, like fittings and pipes, for specific purposes sometimes internally equipped with layers of materials of a completely different quality as the flanges themselves, which are “lined flanges”.

The material of a flange, is basically set during the choice of the pipe, in most cases, a flange is of the same material as the pipe.

The most common materials for pipe flanges (forged grades) are: ASTM A105 (carbon steel high temperature to match A53/A106/API 5L pipes), A350 Grades LF1/2/3 (carbon steel low temperature to match A333 pipes), A694 Grades F42 to F80 (high yield carbon steel to match API 5L pipe grades), ASTM A182 Grades F5 to F91 (alloy steel flanges to match A335 pipes), A182 Grade F304/316 (stainless steel flanges to match A312 SS pipes), A182 Gr. F44/F51/F53/F55 (duplex and super duplex to match A790/A928 pipes) and various nickel alloy grades (Inconel, Incoloy, Hastelloy, Monel).

Specifications :

Size | ½” (15 NB) to 48″ (1200NB) |

Standards | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

Pressure Ratings | Class 150, Class 300, Class 400, Class 600, Class 900, Class1500, Class 2500 | PN6, PN10, PN16, PN25, PN40, PN64 etc. |

Type | Blind Flanges Exporter, Screwed Flanges, Weld Neck Flanges, Lapped joint Flanges, Reducing Flanges |

Material of Construction | Standard | Grades |

Carbon Steel Flanges | ASTM A105 | Gr. F42,46,52,56,60,65,70 |

Alloy Steel | ASTM A182 | F1,F5,F9,F11,F22,F91 |

Stainless Steel Flanges | ASTM A182 , A240 | F 304, 304L, 304H, 316, 316Ti, 316H, 316L, 316LN, 309S, 309H, 310S, 310H,317, 317L, 321, 321H, 347, 347H, 201, 202, 904L |

Duplex Steel Flanges | ASTM / ASME A/SA 182 | F 44, F 45, F51, F 53, F 55, F 60, F 61 |

Monel Flanges | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. | Monel 400 (UNS No. N04400) |

Monel K500 Flanges | ASTM / ASME SB 564 | Monel 500 (UNS No. N05500) |

Inconel Flanges | Inconel 600 | UNS N06600, Werkstoff Nr. 2.4816 |

Inconel 600 Flanges | ASTM B 564/ ASME SB 564 | UNS N06600 / Werkstoff Nr. 2.4816 |

Material | 1. Stainless Steel ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, |

Dimension | DIN2527, DIN2573, DIN2576, DIN2502, DIN2503, DIN2543, DIN2544, DIN2545, DIN2630, DIN2631, |

Size | DN10 ~ DN4000 |

Pressure | PN1, PN2.5, PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160, PN250, PN320, PN400 |

Type | Blind, Slip-On, Weld Neck, Lapped (Lapped Joint), Plain Collar, Loose Flange and Ring for Weld |

Face Type | Flat Face (FF), Raise Face (RF), Ring Joint (RJT) |

Coating | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanize |

EN 1092-1 is a specification for steel flanges. The EN 1092-1 Flanges are one of the most common flanges used worldwide. They can be used for various applications across a wide range of industries, such as, mining, oil and gas, etc. The European rated EN 1092-1 Flanges are also specified in other standards like BS4504 and AS4331 apart from the EN 1092-1. It has evolved from the standard DIN 2501.

The EN 1092-1 Flanges are available with pressure ratings ranging between PN 25 to PN 420. They are available in different shapes, sizes, and dimensions according to the given requirements. The EN 1092-1 Flanges are also typically used in the petrochemical and allied industries.

| BS EN 1092-1:2002 | Flanges and their joints. Circular flanges for pipes, valves, fittings and accessories, PN designated. Steel flanges |

|---|---|

| BS EN 1092-2:1997 | Flanges and their joints. Circular flanges for pipes, valves, fittings and accessories, PN designated. Cast iron flanges |

| BS EN 1092-3:2003 | Flanges and their joints. Circular flanges for pipes, valves, fittings and accessories, PN designated. Copper alloy flanges |

| BS EN 1092-4:2002 | Flanges and their joints. Circular flanges for pipes, valves, fittings and accessories, PN designated. Aluminium alloy flanges |

| BS EN 1515-1:2000 | Flanges and their joints- Bolting: selection of bolting. |

| BS EN 1515-2:2000 | Classification of bolt material for steel flanges PN designated. |

EN 1092-1 standard has the basic flange forms, such as blind flange,weld neck flange, lappedthe flange, threaded Flange, pressed collars , weld on collar, and adapter flange such as flange coupling GD pressfittings. The different forms of flanges within the Flange EN 1092-1 is indicated within the flange name through the type.

| Design | According to EN Type |

|---|---|

| Weld Neck Flange | Type 11 |

| Blind Flange | Type 05 |

| Threaded Flange | Type 12 |

| Flat Flange | Type 01 |

| Lapped Flange | Type 02 & Type 04 |

Size: 1/2″(15 NB) to 48″(1200NB)

Standards: BS EN1092

Pressure Ratings: Class 150, Class 300, Class 400, Class 600, Class 900,Class1500, Class 2500 | PN6, PN10, PN16, PN25,PN40, PN64 etc.

Flange Face Type: Flat Face (FF), Raised Face (RF), Ring Type Joint(RTJ)

Coating/Surface Treatment: Anti-rust Paint, Oil Black Paint,Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

Material | 1. Stainless Steel ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, |

Dimension | JIS B2220 |

Size | 3/8″ (10A) ~ 60″ (1500A) |

Pressure | 2K, 5K, 10K, 16K, 20K, 30K, 40K and 63K |

Type | Blind, Slip-On, Plate, Weld Neck |

Face Type | Flat Face (FF), Raise Face (RF) |

Coating | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanize |

Gost flange is a flange system from Russia, include Plate Flanges(GOST12820-80),Blind Flanges(GOST12836-67),Welding neck Flanges(GOST12821-80), Steel Butt-Welded Flanges GOST12821-80 etc., size from DN10 to DN1600, Plate flange, welding neck flange, slip on welding plate flange.

Pressure, PN 0,1-0,6; 1,0-6,3; 10; 16; 20 MPa

Diameter nominal DN, mm: 10-1600, 10-1200, 10-400, 15-300, 15-200

Materials: steel 3сп, 20, 25, 09Г2С, 10Г2, 15Х5М, 12Х18Н10Т,gost CT20

STANDARD | Type | Pressure | Material | size | Process | Surface treatment |

GOST33259 GOST12820 GOST12821 GOST12836 | SO,BLIND,WN | PN06,PN10,PN16, PN25,PN40,PN64, PN100, | carbon steel stainless steel | DN15-DN3000 | FORGED, FORGING | Light oil |

Rubber expansion joint is a flexible connector fabricated of natural and/or synthetic elastomers and fabric, if necessary, internal metallic reinforcements designed to provide stress relief in piping systems due to thermal movements and mechanical vibration.

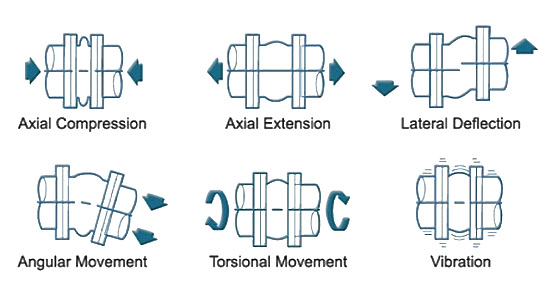

There are lots of material selection based on usage area of rubber expansion joints. Also rubber expansion joints have advantages and disadvantages between of the metal expansion joints. Rubber expansion joints can absorb large movement in very short distance. They provide all directional movement, such as axial, angular, lateral and torsional that may occur from external conditions. Also reduce wind, shock loading and seismic movements.

APPLICATION AREAS

• Heating and cooling devices

• Materials handling technologies

• Water pipes

• Desalination plants

• Compressors

• Blowers and fans

• Cement industry

• Chemical industry

• Glass industy

• Wood-processing industry

• Pulp and paper industry

• Railed vehicles

• Refineries

• Shipbuilding

• Steel mills

• Sugar industry

ADVANTAGES

Spherical joints have a distinct advantage over metallic expansion joints for corrosive applications and installations requiring a high cycle life. The contour prevents sediment accumulation and creates less turbulence and pressure drop than spool joints. The seal bead eliminates any requirement for gaskets between mating flanges. Spheres may be installed on raised-face or flat-face flanges.

COMPARISON AGAINST METAL EXPANSION JOINTS

Temperature: Rubber joints with standard construction and materials have an upper range to 110°C. Can be offer special constructions up to 200°C. Metal expansion joints do offer a far greater range, from -250°C to +950°C.

Features

1) Designed according to ANSI, DIN and BS

2) Type: Single sphere joint flange type

3) Main body: EPDM, NBR, neoprene

4) Lining: Chinlon cord fabrics

5) Frame: Hard steel wires

6) Flange: Carbon steel, stainless steel

7) Union: Malleable iron

9) Size: 1/2″ to 24″

Flange Adaptor is for joining a flanged part to the spigot end of pipes or tubes

Used to connect networks composed of different materials or specially designed for one material, flange adaptors join a flanged part to the spigot end of a pipe or tube. They come in anchoring or non-anchoring versions, while the self-anchoring (locking) products do not necessitate concrete anchor blocks.

Available products

- UltraQuick flange adaptor

- Very broad tolerance for use with a variety of materials

- Can be fitted to grey cast iron, ductile cast iron and fibre cement pipes as well as to steel or PVC tubes

- Available for continuous lengths of pipe with exterior diameters between DE 49 and 348 mm and a PFA of 16 bar

- Substantial angular deflection at approximately 6°

- Multi-pitch circle flange PN 10 and 16

- Quick GS, flange adaptor for ductile iron pipes

- Available from DN 60 to DN 200 in the anchoring version and from DN 60 to DN 300 in the non-anchoring version

- PFA of 16 bar for both versions

- Multi-pitch circle flange PN 10 and 16

- Quick GS, flange adaptor for ductile iron pipes with large diameters

- Available from DN 350 to DN 1000 in a non-anchoring version

- PFA of between 10 and 16 bar

- Quick PVC automatic anchoring flange adaptor for PVC

- Available from DN 40/DE 40 to DN 200/DE 225 in anchoring and non-anchoring versions

- PFA of 16 bar for both versions

- Multi-pitch circle flange with PN 10 and 16

- A simple or anchored QuickBlutop range exists for possible assembly only on BLUTOP (DE 60 to DE 150 mm) pipes

- Quick PE mechanical anchoring flange adaptor for PE

- Available from DN 50/DE 63 to DN 400/DE 400

- PFA of 16 bars

- Multi-pitch circle flange with PN 10 and 16