Boiler Tube

ASTM A213 Seamless Boiler Tube

SA213 T2 is the steel grade in ASME SA213M standard. It is a 1 / 2cr-1 / 2Mo type steel developed on the basis of 1 / 2Mo steel. It is a ferritic hot strength steel for boiler and superheater.

SA213 T2 seamless steel tubes are mainly used for superheater and reheater system with working temperature lower than 540 ℃, and also for water wall tube in supercritical boiler.

SA213 T2 steel,because the steel contains chromium, which can prevent the tendency of graphitization, after long-term use at 480-540 ℃, the mechanical properties and microstructure are stable enough, and the pipe processing and welding properties are good.

ASTM A213 T2 Seamless Steel Tubes Quick Details

Manufacture:Seamless process ,Hot-finished or Cold-finished

Wall thickness(WT): 0.9 mm——12.7 mm.

Outer diameter (OD): 12.7 mm——127 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Threaded

Chemical composition (%)

| Grade | Chemical composition | ||||||

| C | Si | Mn | P | S | Cr | Mo | |

| SA213 T2 | 0.10-0.20 | 0.10-0.30 | 0.30-0.61 | ≤0.025 | ≤0.025 | 0.50-0.81 | 0.44-0.65 |

Metallographic structure

The delivery state of ASME SA213 T2 seamless steel tubes are normalizing and tempering, and the microstructure is ferrite + sorbite.

Mechanical properties

Mechanical properties at room temperature

| Grade | Mechanical properties at room temperature | |||

| Tensile strength | Yield strength | Elongation | HardnessHB(HRB) | |

| SA-213 T2 | ≥ 415 | ≥205 | ≥ 30 | ≤163(85) |

Oxidation resistance

SA213 T2 steel is mainly used in Superheater and reheater system with working temperature lower than 540 ℃, and its oxidation resistance is better than that of carbon steel and carbon manganese steel.

Welding performance

SA213 T2 steel has good welding performance, generally it can be annealed at 650 ~ 700 ℃ after welding without preheating. Heat 207 for manual welding rod and h12crmo / jgs-1cm for GTAW.

Tubes bending

ASME SA213 T2 seamless steel tubes are suitable for all kinds of bending processes. After cold bending, it needs to be de stressed; when the temperature of hot bending exceeds the tempering temperature, it should be re normalized and re ignited.

T5 steel belongs to the ASTM A213 standard ferritic steel. It has good heat resistance and corrosion resistance, and has good cold and hot processing performance. It is widely used in industrial heat exchangers in petrochemical engineering.

Standard: ASTM A213/ASME SA213

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASTM A213 T5 Seamless Alloy-Steel Tubes Quick Details

Manufacture:Seamless process ,Cold-drawn

Wall thickness(WT): 0.9 mm-12.7 mm.

Outer diameter (OD): 12.7 mm-127 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Threaded

ASTM A213 T5 Seamless Alloy-Steel Tubes Chemical Composition(%)

| Grade | Chemical Composition(%) | ||||||

| C | Mn | P | S | Si | Cr | Mo | |

| A213 T5 | ≤0.15 | 0.30-0.60 | ≤0.025 | ≤0.025 | ≤0.50 | 4.00-6.00 | 0.45-0.65 |

ASTM A213 T5 Seamless Alloy-Steel Tubes Mechanical & Physical Properties

| Grade | Mechanical property | |||

| Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) | Hardness(HB) | |

| A213 T5 | ≥415 | ≥205 | 30 | ≤163 |

Note: Mechanical property requirements do not apply to tubing smaller than 1⁄8 in. [3.2 mm] in inside diameter or thinner than 0.015 in. [0.4 mm] in thickness.

Grain Size

Grain size shall be as given in Table 1,

Grain size determinations, shall be made on one end of one finished tube from each lot.

Heat Treatment:

ASTM A213 T5 Seamless Alloy-Steel Boiler Tubes shall be reheated for heat treatment in accordance with the requirements of Table 1. Heat treatment shall be carried out separately and in addition to heating for hot forming.

| Grade | UNS Number | Heat Treat Type | Austenitizing/ Solutioning Temperature, min or range ºF [ºC] | Cooling Media | Subcritical Annealing or Tempering Temperature, min or range ºF [ºC] | |

| ASTM Grain Size No.B | ||||||

| Ferritic Alloy Steels | ||||||

| T5 | K41545 | full or isothermal anneal | … | … | … | … |

| normalize and temper | … | … | 1250 [675] | … | ||

B ASTM Grain Size No. listed, or coarser, unless otherwise indicated.

The dimensional tolerances of ASTM A213 Seamless Boiler Tubes

Tolerances of Wall Thickness

| Wall Thickness, % | ||||||||

| Outside Diameter in. [mm] | 0.095 [2.4] and Under | Over 0.095 to 0.150 [2.4 to 3.8], incl | Over 0.150 to 0.0180 [3.8 to 4.6], incl | Over 0.180 [4.6] | ||||

| Over | Under | Over | Under | Over | Under | Over | Under | |

| Seamless, Hot-Finished Tubes | ||||||||

| 4 [100] and under | 40 | 0 | 35 | 0 | 33 | 0 | 28 | 0 |

| Over 4 [100] | …. | …. | 35 | 0 | 33 | 0 | 28 | 0 |

| Seamless, Cold-Finished Tubes | ||||||||

| Over | Under | |||||||

| 1 1 ⁄ 2 [38.1] and under | 20 | 0 | ||||||

| Over 1 1 ⁄ 2 [38.1] | 22 | 0 | ||||||

Tolerances of Outside Diameter

| Pecified Outside Diameter,in. [mm] | Permitted Variations, in. [mm] | |

| Over | Under | |

| Hot-Finished Seamless Tubes | ||

| 4 [100] or under | 1 ⁄ 64 [0.4] | 1 ⁄ 32 [0.8] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 1 ⁄ 64 [0.4] | 3 ⁄ 64 [1.2] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 1 ⁄ 64 [0.4] | 1 ⁄ 16 [1.6] |

| Cold-Finished Seamless Tubes | ||

| Under 1 [25] | 0.004 [0.1] | 0.004 [0.11] |

| 1 to 1 1 ⁄ 2 [25 to 40], incl | 0.006 [0.15] | 0.006 [0.15] |

| Over 1 1 ⁄ 2 to 2 [40 to 50], excl | 0.008 [0.2] | 0.008 [0.2] |

| 2 to 2 1 ⁄ 2 [50 to 65], excl | 0.010 [0.25] | 0.010 [0.25] |

| 2 1 ⁄ 2 to 3 [65 to 75], excl | 0.012 [0.3] | 0.012 [0.3] |

| 3 to 4 [75 to 100], incl | 0.015 [0.38] | 0.015 [0.38] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 0.015 [0.38] | 0.025 [0.64] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 0.015 [0.38] | 0.045 [1.14] |

Tolerances of Length

| Method of Manufacture | Specified Outside Diameter, in.[mm] | Cut Length, in. [mm] | |

| Over | Under | ||

| Seamless, hot-finished | All sizes | 3 ⁄ 16 [5] | 0 [0] |

| Seamless, cold-finished | Under 2 [50.8] | 1 ⁄ 8 [3] | 0 [0] |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

Tests and Inspection

Tension Tests— One tension test shall be made on a specimen from one tube for lots of not more than 50 tubes. Tension tests shall be made on specimens from two tubes for lots of more than 50 tubes.

Flattening Test—One flattening test shall be made on specimens from each end ofone finished tube, not the one used for the flaring test, from each lot. .

Flaring Test—One flaring test shall be made on specimens from each end of one finished tube, not the one used for the flattening test, from each lot.

Hydrostatic or Nondestructive Electric Test—Each tube shall be subjected to the nondestructive electric test or the hydrostatic test.

Hardness Tests—Brinell, Vickers, or Rockwell hardness tests shall be made on specimens from two tubes from each lot.

Surface Condition

ASTM A213 T5 Seamless Ferritic alloy cold-finished steel tubes shall be free of scale and suitable for inspection. A slight amount of oxidation is not considered scale.

ASTM A213 T5 Seamless Ferritic alloy hot-finished steel tubes shall be free of loose scale and suitable for inspection.

Any special finish requirement be subject to agreement between the supplier and the purchaser.

Process performance and welding performance of ASTM A213 T5 steel

(1) The 5 carbon equivalent is:

m(C) Electricity (T5)=1.58%>0.60%. According to the calculation results, T5 steel has a high tendency to harden, which is a difficult-to-weld material and requires strict process measures such as higher preheating temperature.

(2) Poor welding performance. Due to the tendency of void quenching, the weld and heat-affected zone after welding have high hardness and poor plasticity. Preheat to 250-350℃ before welding. When using chlorine arc welding, the lower limit of preheating temperature can be reduced by 50℃. After welding, cool slowly, avoid cooling to room temperature as much as possible, and go through high temperature tempering at 750-780℃ to improve the mechanical properties of welded joints.

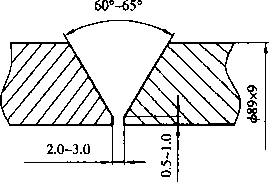

Groove processing of ASTM A213 T5 seamless steel pipe

(1) Since ASTM A213 T5 seamless steel pipes have a strong tendency to harden, the groove should be processed by machining, and the hardened layer at 20mm on the surface and edge of the groove must be polished clean.

(2) The groove form is shown in the figure.

ASTM A213 T9 Seamless Ferritic Alloy-Steel Boiler Tubes.ASTM A213 T9 Seamless Ferritic Alloy-Steel Boiler Tubes are made by the seamless process and shall be either hot finished or cold finished, as specified.

Standard:ASTM A213/ASME SA213

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASTM A213 covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes,.

ASTM A213 T9 Seamless Ferritic Alloy-Steel Boiler Tubes sizes and thicknesses usually furnished to this specification are 1 ⁄ 8 in. [3.2 mm] in inside diameter to 5 in [127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in minimum wall thickness.

Manufacture:Seamless process ,Hot-finished or Cold-finished

Wall thickness(WT): 0.9 mm——12.7 mm.

Outer diameter (OD): 12.7 mm——127 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Threaded

Specification of ASTM A213 T9 Boiler Tubes

| OD (mm) | Wall Thickness(mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

Materials and Manufacture

ASTM A213 T9 Seamless Ferritic Alloy-Steel Boiler Tubes are made by the seamless process and shall be either hot finished or cold finished, as specified.

Grain Size

Grain size shall be as given in Table 1,

Grain size determinations, shall be made on one end of one finished tube from each lot.

Heat Treatment:

| Grade | UNS Number | Heat Treat Type | Subcritical Annealing or Tempering Temperature, min or range ºF [ºC] | ASTM Grain S |

| T9 | S50400 | full or isothermal anneal | … | … |

| normalize and temper | 1250 [675] | … |

Note:1.Heat treatment shall be carried out separately and in addition to heating for hot forming.

2.ASTM Grain Size No. listed, or coarser, unless otherwise indicated.

Chemical Composition of ASTM A213 T9 Seamless Boiler Tubes

| Grade | Chemical Composition(%) | ||||||

| C | Mn | P | S | Si | Cr | Mo | |

| A213 T9 | ≤0.15 | 0.30-0.60 | ≤0.025 | ≤0.025 | 0.25-1.00 | 8.00-10.0 | 0.90-1.10 |

Mechanical Properties of ASTM A213 T9 Seamless Boiler Tubes

| Low Alloy Steels | ||||||

| Grade | UNS Designation | Tensile Strength, min, ksi [MPa] | Yield Strength, min, ksi [MPa] | Elongation in 2 in. or 50 mm,min, % | Hardness | |

| Brinell/Vickers | Rockwell | |||||

| T9 | K90941 | 60 [415] | 30 [205] | 30 | 179 HBW/ 190HV | 89 HRB |

Mechanical property requirements do not apply to tubing smaller than 1 ⁄ 8in. [3.2 mm] in inside diameter or thinner than 0.015 in. [0.4 mm] in thickness.

The dimensional tolerances of ASTM A213 Seamless Boiler Tubes

Tolerances of Wall Thickness

| Wall Thickness, % | ||||||||

| Outside Diameter in. [mm] | 0.095 [2.4] and Under | Over 0.095 to 0.150 [2.4 to 3.8], incl | Over 0.150 to 0.0180 [3.8 to 4.6], incl | Over 0.180 [4.6] | ||||

| Over | Under | Over | Under | Over | Under | Over | Under | |

| Seamless, Hot-Finished Tubes | ||||||||

| 4 [100] and under | 40 | 0 | 35 | 0 | 33 | 0 | 28 | 0 |

| Over 4 [100] | …. | …. | 35 | 0 | 33 | 0 | 28 | 0 |

| Seamless, Cold-Finished Tubes | ||||||||

| Over | Under | |||||||

| 1 1 ⁄ 2 [38.1] and under | 20 | 0 | ||||||

| Over 1 1 ⁄ 2 [38.1] | 22 | 0 | ||||||

Tolerances of Outside Diameter

| Pecified Outside Diameter,in. [mm] | Permitted Variations, in. [mm] | |

| Over | Under | |

| Hot-Finished Seamless Tubes | ||

| 4 [100] or under | 1 ⁄ 64 [0.4] | 1 ⁄ 32 [0.8] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 1 ⁄ 64 [0.4] | 3 ⁄ 64 [1.2] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 1 ⁄ 64 [0.4] | 1 ⁄ 16 [1.6] |

| Cold-Finished Seamless Tubes | ||

| Under 1 [25] | 0.004 [0.1] | 0.004 [0.11] |

| 1 to 1 1 ⁄ 2 [25 to 40], incl | 0.006 [0.15] | 0.006 [0.15] |

| Over 1 1 ⁄ 2 to 2 [40 to 50], excl | 0.008 [0.2] | 0.008 [0.2] |

| 2 to 2 1 ⁄ 2 [50 to 65], excl | 0.010 [0.25] | 0.010 [0.25] |

| 2 1 ⁄ 2 to 3 [65 to 75], excl | 0.012 [0.3] | 0.012 [0.3] |

| 3 to 4 [75 to 100], incl | 0.015 [0.38] | 0.015 [0.38] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 0.015 [0.38] | 0.025 [0.64] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 0.015 [0.38] | 0.045 [1.14] |

Tolerances of Length

| Method of Manufacture | Specified Outside Diameter, in.[mm] | Cut Length, in. [mm] | |

| Over | Under | ||

| Seamless, hot-finished | All sizes | 3 ⁄ 16 [5] | 0 [0] |

| Seamless, cold-finished | Under 2 [50.8] | 1 ⁄ 8 [3] | 0 [0] |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

Hydrostatic or Nondestructive Electric Test

Each tube will be subjected to the nondestructive electric test or the hydrostatic test.

Tests

(1)Tension test——One tension test shall be made on a specimen from one tube for lots of not more than 50 tubes. Tension tests shall be made on specimens from two tubes for lots of more than 50 tubes.

(2)Hardness Requirements—— Brinell, Vickers, or Rockwell hardness tests shall be made on specimens from two tubes from each lot. See (3)Flattening Test——One flattening test shall be made on specimens from each end of one finished tube.

(4)Flaring Test——One flaring test shall be made on specimens from each end of one finished tube.

Surface Condition

ASTM A213 T9 Ferritic alloy cold-finished steel tubes are free of scale and suitable for inspection.

ASTM A213 T9 Ferritic alloy hot-finished steel tubes are free of loose scale and suitable for inspection.

Note: Material furnished under ASTM A213 conform to the applicable requirements of the current edition of Specification A1016/A1016M

STM A213 T9 Seamless Boiler Tubes Marking

In addition to the marking prescribed in Specification ASTM A1016/A1016M, the marking shall indicate whether the tube is hot-finished or cold-finished.

ASTM A213 T11 Seamless Ferritic Alloy-Steel Boiler Tubes sizes and thicknesses usually furnished to this specification are 1⁄8 in.in inside diameter to 5in,in outside diameter and 0.015 to 0.500in,inclusive,in minimum wall thickness.

Standard:ASTM A213/ASME SA213

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASTM A213 covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes,.

ASTM A213 T11 Seamless Ferritic Alloy-Steel Boiler Tubes sizes and thicknesses usually furnished to this specification are 1 ⁄ 8 in. [3.2 mm] in inside diameter to 5 in [127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in minimum wall thickness.

Manufacture:Seamless process ,Hot-finished or Cold-finished

Wall thickness(WT): 0.9 mm——12.7 mm.

Outer diameter (OD): 12.7 mm——127 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Threaded

Specification of ASTM A213 T11 Boiler Tubes

| OD (mm) | Wall Thickness(mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

Materials and Manufacture

ASTM A213 T11 Seamless Ferritic Alloy-Steel Boiler Tubes are made by the seamless process and shall be either hot finished or cold finished, as specified.

Grain Size

Grain size shall be as given in Table 1,

Grain size determinations, shall be made on one end of one finished tube from each lot.

Heat Treatment of ASTM A213 T11

| Grade | UNS Number | Heat Treat Type | Austenitizing/ Solutioning Temperature, min or range ºF [ºC] | Cooling Media | Subcritical Annealing or Tempering Temperature, min or range ºF [ºC] | ASTM Grain S |

| Ferritic Alloy Steels | ||||||

| T11 | K11597 | full or isothermal anneal | … | … | … | … |

| normalize and temper | … | … | 1200 [650] | … | ||

Note:1.Heat treatment shall be carried out separately and in addition to heating for hot forming.

2.ASTM Grain Size No. listed, or coarser, unless otherwise indicated.

Chemical Composition of ASTM A213 T11 Seamless Boiler Tubes

| Grade | Chemical Composition(%) | ||||||

| C | Mn | P | S | Si | Cr | Mo | |

| A213 T11 | 0.05-0.15 | 0.30-0.60 | ≤0.025 | ≤0.025 | 0.50-1.00 | 1.00-1.50 | 0.45-0.65 |

Mechanical Properties of ASTM A213 T11 Seamless Boiler Tubes

| Grade | Tensile Strength, min, ksi [MPa] | Yield Strength, min, ksi [MPa] | Elongation in 2 in. or 50 mm,min, % | Hardness | |

| Brinell/Vickers | Rockwell | ||||

| T11 | 60 [415] | 30 [205] | 30 | 179 HBW/ 190HV | 89 HRB |

Mechanical property requirements do not apply to tubing smaller than 1 ⁄ 8in. [3.2 mm] in inside diameter or thinner than 0.015 in. [0.4 mm] in thickness.

The dimensional tolerances of ASTM A213 Seamless Boiler Tubes

Tolerances of Wall Thickness

| Wall Thickness, % | ||||||||

| Outside Diameter in. [mm] | 0.095 [2.4] and Under | Over 0.095 to 0.150 [2.4 to 3.8], incl | Over 0.150 to 0.0180 [3.8 to 4.6], incl | Over 0.180 [4.6] | ||||

| Over | Under | Over | Under | Over | Under | Over | Under | |

| Seamless, Hot-Finished Tubes | ||||||||

| 4 [100] and under | 40 | 0 | 35 | 0 | 33 | 0 | 28 | 0 |

| Over 4 [100] | …. | …. | 35 | 0 | 33 | 0 | 28 | 0 |

| Seamless, Cold-Finished Tubes | ||||||||

| Over | Under | |||||||

| 1 1 ⁄ 2 [38.1] and under | 20 | 0 | ||||||

| Over 1 1 ⁄ 2 [38.1] | 22 | 0 | ||||||

Tolerances of Outside Diameter

| Pecified Outside Diameter,in. [mm] | Permitted Variations, in. [mm] | |

| Over | Under | |

| Hot-Finished Seamless Tubes | ||

| 4 [100] or under | 1 ⁄ 64 [0.4] | 1 ⁄ 32 [0.8] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 1 ⁄ 64 [0.4] | 3 ⁄ 64 [1.2] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 1 ⁄ 64 [0.4] | 1 ⁄ 16 [1.6] |

| Cold-Finished Seamless Tubes | ||

| Under 1 [25] | 0.004 [0.1] | 0.004 [0.11] |

| 1 to 1 1 ⁄ 2 [25 to 40], incl | 0.006 [0.15] | 0.006 [0.15] |

| Over 1 1 ⁄ 2 to 2 [40 to 50], excl | 0.008 [0.2] | 0.008 [0.2] |

| 2 to 2 1 ⁄ 2 [50 to 65], excl | 0.010 [0.25] | 0.010 [0.25] |

| 2 1 ⁄ 2 to 3 [65 to 75], excl | 0.012 [0.3] | 0.012 [0.3] |

| 3 to 4 [75 to 100], incl | 0.015 [0.38] | 0.015 [0.38] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 0.015 [0.38] | 0.025 [0.64] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 0.015 [0.38] | 0.045 [1.14] |

Tolerances of Length

| Method of Manufacture | Specified Outside Diameter, in.[mm] | Cut Length, in. [mm] | |

| Over | Under | ||

| Seamless, hot-finished | All sizes | 3 ⁄ 16 [5] | 0 [0] |

| Seamless, cold-finished | Under 2 [50.8] | 1 ⁄ 8 [3] | 0 [0] |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

Hydrostatic or Nondestructive Electric Test

Each tube will be subjected to the nondestructive electric test or the hydrostatic test.

Tests

(1)Tension test——One tension test shall be made on a specimen from one tube for lots of not more than 50 tubes. Tension tests shall be made on specimens from two tubes for lots of more than 50 tubes.

(2)Hardness Requirements—— Brinell, Vickers, or Rockwell hardness tests shall be made on specimens from two tubes from each lot.

(3)Flattening Test——One flattening test shall be made on specimens from each end of one finished tube.

(4)Flaring Test——One flaring test shall be made on specimens from each end of one finished tube.

Surface Condition

ASTM A213 T11 Ferritic alloy cold-finished steel tubes are free of scale and suitable for inspection.

ASTM A213 T11 Ferritic alloy hot-finished steel tubes are free of loose scale and suitable for inspection.

Note: Material furnished under ASTM A213 conform to the applicable requirements of the current edition of Specification A1016/A1016M

ASTM A213 T11 Seamless Boiler Tubes Marking

In addition to the marking prescribed in Specification ASTM A1016/A1016M, the marking shall indicate whether the tube is hot-finished or cold-finished.

A213 T12 steel tubes are widely used in boiler superheater, reheater and other heating surface piping, header and main steam pipeline with working temperature not exceeding 550 ℃ such as 300MW and 600MW.

ASTM A213 T12 belongs to 1Cr-1 / 2Mo pearlescent low alloy hot strength steel. A213t12 steel has good processing and welding properties, and has high thermal strength and oxidation resistance under 550 ℃.

Standard:ASTM A213/ASME SA213

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes.

| Standard | Grade |

| ASTM A213 | T12 |

| GB5310 | 15CrMoG |

Wall thickness(WT): 0.9 mm——12.7 mm.

Outer diameter (OD): 12.7 mm——127 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Threaded

Specification of ASTM A213 T12 Boiler Tubes

| OD (mm) | Wall Thickness(mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

Materials and Manufacture

ASTM A213 T12 Seamless Ferritic Alloy-Steel Boiler Tubes are made by the seamless process and shall be either hot finished or cold finished, as specified.

Grain Size

Grain size shall be as given in Table 1,

Grain size determinations, shall be made on one end of one finished tube from each lot.

Heat Treatment of ASTM A213 T12

| Grade | UNS Number | Heat Treat Type | Austenitizing/ Solutioning Temperature, min or range ºF [ºC] | Cooling Media | Subcritical Annealing or Tempering Temperature, min or range ºF [ºC] | |

| ASTM Grain S | ||||||

| Ferritic Alloy Steels | ||||||

| T12 | K11562 | full or isothermal anneal | … | … | … | … |

| normalize and temper | … | … | … | … | ||

| subcritical anneal | … | … | 1200 to 1350[650 to 730] | … | ||

Note:1.Heat treatment shall be carried out separately and in addition to heating for hot forming.

2.ASTM Grain Size No. listed, or coarser, unless otherwise indicated.

Chemical Composition of ASTM A213 T12 Seamless Boiler Tubes

| Grade | Chemical Composition(%) | ||||||

| C | Mn | P | S | Si | Cr | Mo | |

| A213 T12 | 0.05-0.15 | 0.30-0.60 | ≤0.025 | ≤0.025 | ≤0.50 | 0.80-1.25 | 0.45-0.65 |

Mechanical Properties of ASTM A213 T12 Seamless Boiler Tubes

| Low Alloy Steels | ||||||

| Grade | UNS Designation | Tensile Strength, min, ksi [MPa] | Yield Strength, min, ksi [MPa] | Elongation in 2 in. or 50 mm, min, % | Hardness | |

| Brinell/Vickers | Rockwell | |||||

| T12 | K11562 | 60 [415] | 32 [220] | 30 | 163 HBW/ 170 HV | 85 HRB |

Mechanical property requirements do not apply to tubing smaller than 1 ⁄ 8in. [3.2 mm] in inside diameter or thinner than 0.015 in. [0.4 mm] in thickness.

The dimensional tolerances of ASTM A213 Seamless Boiler Tubes

Tolerances of Wall Thickness

| Wall Thickness, % | ||||||||

| Outside Diameter in. [mm] | 0.095 [2.4] and Under | Over 0.095 to 0.150 [2.4 to 3.8], incl | Over 0.150 to 0.0180 [3.8 to 4.6], incl | Over 0.180 [4.6] | ||||

| Over | Under | Over | Under | Over | Under | Over | Under | |

| Seamless, Hot-Finished Tubes | ||||||||

| 4 [100] and under | 40 | 0 | 35 | 0 | 33 | 0 | 28 | 0 |

| Over 4 [100] | …. | …. | 35 | 0 | 33 | 0 | 28 | 0 |

| Seamless, Cold-Finished Tubes | ||||||||

| Over | Under | |||||||

| 1 1 ⁄ 2 [38.1] and under | 20 | 0 | ||||||

| Over 1 1 ⁄ 2 [38.1] | 22 | 0 | ||||||

Tolerances of Outside Diameter

| Pecified Outside Diameter,in. [mm] | Permitted Variations, in. [mm] | |

| Over | Under | |

| Hot-Finished Seamless Tubes | ||

| 4 [100] or under | 1 ⁄ 64 [0.4] | 1 ⁄ 32 [0.8] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 1 ⁄ 64 [0.4] | 3 ⁄ 64 [1.2] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 1 ⁄ 64 [0.4] | 1 ⁄ 16 [1.6] |

| Cold-Finished Seamless Tubes | ||

| Under 1 [25] | 0.004 [0.1] | 0.004 [0.11] |

| 1 to 1 1 ⁄ 2 [25 to 40], incl | 0.006 [0.15] | 0.006 [0.15] |

| Over 1 1 ⁄ 2 to 2 [40 to 50], excl | 0.008 [0.2] | 0.008 [0.2] |

| 2 to 2 1 ⁄ 2 [50 to 65], excl | 0.010 [0.25] | 0.010 [0.25] |

| 2 1 ⁄ 2 to 3 [65 to 75], excl | 0.012 [0.3] | 0.012 [0.3] |

| 3 to 4 [75 to 100], incl | 0.015 [0.38] | 0.015 [0.38] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 0.015 [0.38] | 0.025 [0.64] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 0.015 [0.38] | 0.045 [1.14] |

Tolerances of Length

| Method of Manufacture | Specified Outside Diameter, in.[mm] | Cut Length, in. [mm] | |

| Over | Under | ||

| Seamless, hot-finished | All sizes | 3 ⁄ 16 [5] | 0 [0] |

| Seamless, cold-finished | Under 2 [50.8] | 1 ⁄ 8 [3] | 0 [0] |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

Hydrostatic or Nondestructive Electric Test

Each tube will be subjected to the nondestructive electric test or the hydrostatic test.

Tests

(1)Tension test——One tension test shall be made on a specimen from one tube for lots of not more than 50 tubes. Tension tests shall be made on specimens from two tubes for lots of more than 50 tubes.

(2)Hardness Requirements—— Brinell, Vickers, or Rockwell hardness tests shall be made on specimens from two tubes from each lot.

(3)Flattening Test——One flattening test shall be made on specimens from each end of one finished tube.

(4)Flaring Test——One flaring test shall be made on specimens from each end of one finished tube.

ASTM A213 T12 Seamless Boiler Tubes Marking

In addition to the marking prescribed in Specification ASTM A1016/A1016M, the marking shall indicate whether the tube is hot-finished or cold-finished.

ASTM A213 T22 Seamless Ferritic Alloy-Steel Boiler Tubes are made by the seamless process,ASTM A213 T22 Steel Tubes for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes.

Standard:ASTM A213/ASME SA213

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes.

Wall thickness(WT): 0.9 mm——12.7 mm.

Outer diameter (OD): 12.7 mm——127 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Threaded

| OD (mm) | Wall Thickness(mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

Materials and Manufacture

ASTM A213 T22 Seamless Ferritic Alloy-Steel Boiler Tubes are made by the seamless process and shall be either hot finished or cold finished, as specified.

Grain Size

Grain size shall be as given in Table 1,

Grain size determinations, shall be made on one end of one finished tube from each lot.

Heat Treatment of ASTM A213 T22

| Grade | UNS Number | Heat Treat Type | Austenitizing/ Solutioning Temperature, min or range ºF [ºC] | Cooling Media | Subcritical Annealing or Tempering Temperature, min or range ºF [ºC] | ASTM Grain S |

| Ferritic Alloy Steels | ||||||

| T22 | K21590 | full or isothermal anneal | … | … | … | … |

| normalize and temper | … | 1250 [675] | … | |||

2.ASTM Grain Size No. listed, or coarser, unless otherwise indicated.

Chemical Composition of ASTM A213 T22 Seamless Boiler Tubes

| Grade | Chemical Composition(%) | ||||||

| C | Mn | P | S | Si | Cr | Mo | |

| A213 T22 | 0.05-0.15 | 0.30-0.60 | ≤0.025 | ≤0.025 | ≤0.50 | 1.90-2.60 | 0.87-1.13 |

Mechanical Properties of ASTM A213 T22 Seamless Boiler Tubes

| Grade | Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) | Hardness(HB) |

| A213 T22 | ≥415 | ≥205 | 30 | ≤163 |

The dimensional tolerances of ASTM A213 Seamless Boiler Tubes

Tolerances of Wall Thickness

| Wall Thickness, % | ||||||||

| Outside Diameter in. [mm] | 0.095 [2.4] and Under | Over 0.095 to 0.150 [2.4 to 3.8], incl | Over 0.150 to 0.0180 [3.8 to 4.6], incl | Over 0.180 [4.6] | ||||

| Over | Under | Over | Under | Over | Under | Over | Under | |

| Seamless, Hot-Finished Tubes | ||||||||

| 4 [100] and under | 40 | 0 | 35 | 0 | 33 | 0 | 28 | 0 |

| Over 4 [100] | …. | …. | 35 | 0 | 33 | 0 | 28 | 0 |

| Seamless, Cold-Finished Tubes | ||||||||

| Over | Under | |||||||

| 1 1 ⁄ 2 [38.1] and under | 20 | 0 | ||||||

| Over 1 1 ⁄ 2 [38.1] | 22 | 0 | ||||||

Tolerances of Outside Diameter

| Pecified Outside Diameter,in. [mm] | Permitted Variations, in. [mm] | |

| Over | Under | |

| Hot-Finished Seamless Tubes | ||

| 4 [100] or under | 1 ⁄ 64 [0.4] | 1 ⁄ 32 [0.8] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 1 ⁄ 64 [0.4] | 3 ⁄ 64 [1.2] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 1 ⁄ 64 [0.4] | 1 ⁄ 16 [1.6] |

| Cold-Finished Seamless Tubes | ||

| Under 1 [25] | 0.004 [0.1] | 0.004 [0.11] |

| 1 to 1 1 ⁄ 2 [25 to 40], incl | 0.006 [0.15] | 0.006 [0.15] |

| Over 1 1 ⁄ 2 to 2 [40 to 50], excl | 0.008 [0.2] | 0.008 [0.2] |

| 2 to 2 1 ⁄ 2 [50 to 65], excl | 0.010 [0.25] | 0.010 [0.25] |

| 2 1 ⁄ 2 to 3 [65 to 75], excl | 0.012 [0.3] | 0.012 [0.3] |

| 3 to 4 [75 to 100], incl | 0.015 [0.38] | 0.015 [0.38] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 0.015 [0.38] | 0.025 [0.64] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 0.015 [0.38] | 0.045 [1.14] |

Tolerances of Length

| Method of Manufacture | Specified Outside Diameter, in.[mm] | Cut Length, in. [mm] | |

| Over | Under | ||

| Seamless, hot-finished | All sizes | 3 ⁄ 16 [5] | 0 [0] |

| Seamless, cold-finished | Under 2 [50.8] | 1 ⁄ 8 [3] | 0 [0] |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

Hydrostatic or Nondestructive Electric Test

Each tube will be subjected to the nondestructive electric test or the hydrostatic test.

Tests

(1)Tension test——One tension test shall be made on a specimen from one tube for lots of not more than 50 tubes. Tension tests shall be made on specimens from two tubes for lots of more than 50 tubes.

(2)Hardness Requirements—— Brinell, Vickers, or Rockwell hardness tests shall be made on specimens from two tubes from each lot.

(3)Flattening Test——One flattening test shall be made on specimens from each end of one finished tube.

(4)Flaring Test——One flaring test shall be made on specimens from each end of one finished tube.

Surface Condition

Ferritic alloy cold-finished steel tubes are free of scale and suitable for inspection.

Ferritic alloy hot-finished steel tubes are free of loose scale and suitable for inspection.

Note: Material furnished under ASTM A213 conform to the applicable requirements of the current edition of Specification A1016/A1016M

Application:

ASTM A213 T22 Seamless Boiler Tubes Marking

In addition to the marking prescribed in Specification ASTM A1016/A1016M, the marking shall indicate whether the tube is hot-finished or cold-finished.

ASME SA213 t23: “SA” is a mark of ASME steel material. “213” refers to the specification sequence number, “T23” refers to the steel grade classification, “T” refers to small diameter steel tube, equivalent to 07cr2mow2vnbb small diameter steel tube in China.

SA213 T23 steel is based on the chemical composition of 2.25Cr-1Mo (SA213 T22) steel, adding w (about 1.6%), reducing mo (about 0.30%), and adding a small amount of V, Nb, Ni, B and other components. The allowable stress of T23 Steel is twice that of T22 steel, and the endurance strength at 580 ℃ is 1.4 times that of 12Cr1MoV steel. SA213 T23 steel has the same endurance strength as 12Cr2MoWVTiB (G102) steel, and has high impact toughness and good weldability.

ASME SA213 T23 Seamless Steel Tubes are mainly suitable for manufacturing superheater, reheater and water wall of large-scale utility boiler, and SA213 T23 Seamless Steel Tubes are better choice material for the main steam temperature below 620 ℃.

| Grade | C | Mn | S | P | Si | Cr | Nb |

| SA213 T23 | 0.04-0.10 | 0.10-0.60 | ≤0.01 | ≤0.03 | ≤0.50 | 1.9-2.6 | 0.02-0.08 |

| Mo | V | Al | N | W | B | ||

| 0.05-0.30 | 0.20-0.30 | ≤0.03 | ≤0.40 | 1.45-1.75 | 0.0005-0.0060 | ||

| Grade | Tensile strength Ksi (MPa) | Yield strength Ksi (MPa) | Elongation (%) | Hardness (HB) |

| SA213 T23 | ≥74(510) | ≥58(400) | ≥20 | ≥220 |

| Grade | UNS Number | Heat Treat Type | Austenitizing/ Solutioning Temperature, min or range ºF [ºC] | Subcritical Annealing or Tempering Temperature, min or range ºF [ºC] |

| T23 | K40712 | normalize and temper | 1900–1975[1040–1080] | 1350–1470 [730–800] |

The microstructure of SA213 T23 steel is tempered bainite after normalizing and tempering.

Properties of SA213 T23 steel tubes welded joint

(1)The welding method of sa213t23 steel tubes are hot wire automatic TIG welding, and the welding material is t-hcm2s with a diameter of 1mm

(2)It is not easy to preheat the small and medium diameter steel pipe before welding, so post welding heat treatment should be carried out in the actual production. Considering the safety and stability of the welded joint, the welded joint of SA213 T23 steel tubes should also be subject to post weld heat treatment.

(3)Welding of dissimilar steel:

Application of sa213t23 steel pipe in Utility Boiler

Sa213t23 high pressure boiler tube has been widely used in the construction of power station boilers in China. According to statistics, sa213t23 steel pipe accounts for 11.16% of the steel used in a 1000MW power generation

A-213 T91: “A” is the mark of ASTM steel material. “213” refers to the specification reference number, “T91” refers to the steel grade classification, “T” refers to small diameter pipe, equivalent to China’s 10Cr9Mo1VNbN small diameter pipe.)

A-213 T91 is ASTM A-213 / A-213m standard steel grade: in 1970s, based on 9Cr-1Mo steel, a new type of ferritic shape steel was formed by adding a small amount of Nb and V microalloying elements and controlling the content of n elements in 9Cr-1Mo steel by several laboratories and burnxiao engineering company in the United States. The steel has good comprehensive mechanical properties, stable structure and properties before and after aging, good welding and technological properties, high endurance strength and oxidation resistance. In 1995, the steel was transplanted into GB5310 standard in China, and the grade was 10Cr9Mo1VNb.

Standard:ASTM A213/ASME SA213

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASTM A213 T91 Seamless Ferritic Alloy-Steel Boiler Tubes Quick Details

Manufacture:Seamless process ,Hot-finished or Cold-finished

Wall thickness(WT): 0.9 mm——12.7 mm.

Outer diameter (OD): 12.7 mm——127 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Treaded

Specification of ASTM A213 T91 Boiler Tubes

| OD (mm) | Wall Thickness(mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

Materials and Manufacture

ASTM A213 T91 Seamless Ferritic Alloy-Steel Boiler Tubes are made by the seamless process and shall be either hot finished or cold finished, as specified.

Grain Size

Grain size shall be as given in Table 1,

Grain size determinations, shall be made on one end of one finished tube from each lot.

Heat Treatment of ASTM A213 T91

| Grade | UNS Number | Heat Treat Type | Austenitizing/ Solutioning Temperature, min or range ºF [ºC] | Cooling Media | Subcritical Annealing or Tempering Temperature, min or range ºF [ºC] | ASTM Grain S |

| Ferritic Alloy Steels | ||||||

| T91 | K90901 | normalize and temper | 1900–1975 [1040–1080] | … | 1350–1470 [730–800] | … |

Note:1.Heat treatment shall be carried out separately and in addition to heating for hot forming.

2.ASTM Grain Size No. listed, or coarser, unless otherwise indicated.

Chemical Composition of ASTM A213 T91 Seamless Boiler Tubes

| Chemical Composition(%) | |||||||||||

| C | Mn | P | S | Si | Cr | Mo | V | N | Ni | Al | Nb |

| 0.07-0.14 | 0.3-0.6 | ≤0.02 | ≤0.01 | 0.2-0.5 | 8.0-9.5 | 0.85-1.05 | 0.18-0.25 | 0.03-0.07 | ≤0.4 | ≤0.04 | 0.06-0.10 |

Mechanical Properties of ASTM A213 T91 Seamless Boiler Tubes

| Low Alloy Steels | ||||||

| Grade | UNS Designation | Tensile Strength, min, ksi [MPa] | Yield Strength, min, ksi [MPa] | Elongation in 2 in. or 50 mm, min, % | Hardness | |

| Brinell/Vickers | Rockwell | |||||

| T91 | K90901 | 85 [585] | 60 [415] | 20 | 190 to 250 HBW/ 196 to 265 HV | 90 HRB to 25 |

Mechanical property requirements do not apply to tubing smaller than 1 ⁄ 8in. [3.2 mm] in inside diameter or thinner than 0.015 in. [0.4 mm] in thickness.

The dimensional tolerances of ASTM A213 Seamless Boiler Tubes

Tolerances of Wall Thickness

| Wall Thickness, % | ||||||||

| Outside Diameter in. [mm] | 0.095 [2.4] and Under | Over 0.095 to 0.150 [2.4 to 3.8], incl | Over 0.150 to 0.0180 [3.8 to 4.6], incl | Over 0.180 [4.6] | ||||

| Over | Under | Over | Under | Over | Under | Over | Under | |

| Seamless, Hot-Finished Tubes | ||||||||

| 4 [100] and under | 40 | 0 | 35 | 0 | 33 | 0 | 28 | 0 |

| Over 4 [100] | …. | …. | 35 | 0 | 33 | 0 | 28 | 0 |

| Seamless, Cold-Finished Tubes | ||||||||

| Over | Under | |||||||

| 1 1 ⁄ 2 [38.1] and under | 20 | 0 | ||||||

| Over 1 1 ⁄ 2 [38.1] | 22 | 0 | ||||||

Tolerances of Outside Diameter

| Pecified Outside Diameter,in. [mm] | Permitted Variations, in. [mm] | |

| Over | Under | |

| Hot-Finished Seamless Tubes | ||

| 4 [100] or under | 1 ⁄ 64 [0.4] | 1 ⁄ 32 [0.8] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 1 ⁄ 64 [0.4] | 3 ⁄ 64 [1.2] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 1 ⁄ 64 [0.4] | 1 ⁄ 16 [1.6] |

| Cold-Finished Seamless Tubes | ||

| Under 1 [25] | 0.004 [0.1] | 0.004 [0.11] |

| 1 to 1 1 ⁄ 2 [25 to 40], incl | 0.006 [0.15] | 0.006 [0.15] |

| Over 1 1 ⁄ 2 to 2 [40 to 50], excl | 0.008 [0.2] | 0.008 [0.2] |

| 2 to 2 1 ⁄ 2 [50 to 65], excl | 0.010 [0.25] | 0.010 [0.25] |

| 2 1 ⁄ 2 to 3 [65 to 75], excl | 0.012 [0.3] | 0.012 [0.3] |

| 3 to 4 [75 to 100], incl | 0.015 [0.38] | 0.015 [0.38] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 0.015 [0.38] | 0.025 [0.64] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 0.015 [0.38] | 0.045 [1.14] |

Tolerances of Length

| Method of Manufacture | Specified Outside Diameter, in.[mm] | Cut Length, in. [mm] | |

| Over | Under | ||

| Seamless, hot-finished | All sizes | 3 ⁄ 16 [5] | 0 [0] |

| Seamless, cold-finished | Under 2 [50.8] | 1 ⁄ 8 [3] | 0 [0] |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

Hydrostatic or Nondestructive Electric Test

Each tube will be subjected to the nondestructive electric test or the hydrostatic test.

Tests

(1)Tension test——One tension test shall be made on a specimen from one tube for lots of not more than 50 tubes. Tension tests shall be made on specimens from two tubes for lots of more than 50 tubes.

(2)Hardness Requirements—— Brinell, Vickers, or Rockwell hardness tests shall be made on specimens from two tubes from each lot.

(3)Flattening Test——One flattening test shall be made on specimens from each end of one finished tube.

(4)Flaring Test——One flaring test shall be made on specimens from each end of one finished tube.

Surface Condition

Ferritic alloy cold-finished steel tubes are free of scale and suitable for inspection.

Ferritic alloy hot-finished steel tubes are free of loose scale and suitable for inspection.

Note: Material furnished under ASTM A213 conform to the applicable requirements of the current edition of Specification A1016/A1016M

Application of ASTM a-213 T91 alloy steel pipe:

ASTM A213 T91 Seamless Boiler Tubes Marking

In addition to the marking prescribed in Specification ASTM A1016/A1016M, the marking shall indicate whether the tube is hot-finished or cold-finished.

Ordering Information

It shall be the responsibility of the purchaser to specify all requirements that are necessary for products.

(1) Quantity (feet, metres, or number of lengths)

(2) Name of material (seamless tubes)

(3) Grade (T91)

(4) Condition (hot finished or cold finished)

(5) Size (outside diameter and minimum wall thickness, unless average wall thickness is specified)

(6) Length (specific or random)

(7) Hydrostatic Test or Nondestructive Electric Test

(8) Increased sulfur

SA213 T92 steel tubes can partially replace TP304H and TP347H austenitic stainless steel pipes to manufacture sub-critical, super-critical, or even super-supercritical power plant boilers with metal wall temperatures not exceeding 650℃.

Introduction of SA213 T92 (NF616) steel

T92 (NF616) steel is Nippon Steel based on T91. It has further improved the composition, adopted composite-multiple strengthening methods, appropriately reduced the content of Mo and added W, and formed W-Mo with W as the main component. Composite solid solution strengthening, adding element N to form interstitial solid solution strengthening, adding elements such as V, Nb, and N to form carbonitride dispersion precipitation strengthening, and adding a small amount of B (0.001-0.006%) to form grain boundary strengthening of element B, and T91 The same high Cr content guarantees the same oxidation resistance and corrosion resistance as T91.

T92 steel, like T91 steel, has a better thermal expansion coefficient and thermal conductivity than austenitic steel. It has excellent long-term strength, high allowable stress, good toughness and weldability, and stable structure and performance before and after aging. . The allowable stress is higher than T91 steel, and the allowable stress at 650 ° C is 1.6 times that of T91 steel; and the steam oxidation resistance is better, which is basically the same as T91 steel. The temperature equal to TP347H is 625 ℃. When the temperature is lower than 625 ℃, the lasting strength of T92 steel is higher than TP347H.

ASTM A213 ASME SA213 T92 Seamless Steel Tubes Quick Details

Manufacture:Seamless process ,Hot-finished or Cold-finished

Wall thickness(WT): 7.5mm——32.0 mm.

Outer diameter (OD): 89.9 mm——452.0 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Threaded

Application of SA213 T92 (NF616) steel tubes

SA213 T92 steel tubes have excellent performance, and the use temperature can reach 650 ℃. It can partially replace TP304H and TP347H austenitic stainless steel tubes to manufacture sub-critical, super-critical, or even super-supercritical power plant boilers with metal wall temperatures not exceeding 650 ° C, such as high-temperature superheaters, reheater tubes, and main steam tubes. To avoid or reduce dissimilar steel joints and improve the running performance of steel tubes. If used in subcritical boilers, it can be used instead of TP347H and T91 thick-walled steel tubes.

Chemical composition

| Standard | Grade | Chemical composition(%) | |||||

| C | Mn | Si | P | S | Cr | ||

| SA213 | T92 | 0.07-0.13 | 0.30-0.60 | ≤0.50 | ≤.020 | ≤.010 | 8.0-9.5 |

| Nippon Steel | NF616 | ≤0.15 | ≤1.00 | ≤0.50 | ≤.020 | ≤.010 | 8.0-13.0 |

| Ni | Mo | V | Nb | N | Al | ||

| SA213 | T92 | ≤0.40 | 0.30-0.60 | 0.15-0.25 | 0.04-0.09 | 0.03-0.07 | ≤.040 |

| Nippon Steel | NF616 | — | ≤1.00 | 0.10-0.30 | ≤0.10 | 0.02-0.15 | ≤.040 |

Note 1: It also contains W (tungsten) and B (boron). In the SA213 standard, the specified value of W is 1.50-2.0%, and the specified value of B is 0.001-0.006%.

Note 2: It also contains W (tungsten) and B (boron). The N specified value of Nippon Steel is 1.50-2.0%, and the specified value of B is ≤0.01%.

Mechanical properties

| Mechanical properties at room temperature | ||||

| Standard | Tensile properties (longitudinal) | HardnessHB | ||

| Yield strength(MPa) | Tensile strength(MPa) | Elongation(%) | ||

| SA213 | ≥440 | ≥620 | ≥20 | ≤250 |

| Nippon Steel | ≥440 | ≥590 | ≥20 | ≤250 |

Lasting strength(MPa)of SA213 T92 (NF616) steel tubes

| Standard | 500℃ | 525℃ | 550℃ | 575℃ | 600℃ | 625℃ | 650℃ |

| SA213 | 200 | 165 | 132 | 100 | 72 |

Allowable stress(MPa)of SA213 T92 (NF616) steel tubes

| Temperature℃ | 350℃ | 400℃ | 450℃ | 500℃ | 525℃ | 550℃ | 575℃ | 600℃ | 625℃ | 650℃ |

| Allowable stress | 156.4 | 150.7 | 143.6 | 134.5 | 129.0 | 122.8 | 110.2 | 87.8 | 67.0 | 46.7 |

Antioxidant performance

The steam oxidation resistance tests at 650 and 700 ° C show that the oxidation resistance of SA213 T92 steel tubes at two temperatures is basically the same as that of T91 steel tubes.

Process performance

Heat treatment

The supply status of T92 steel is normalized + tempered. The minimum normalizing temperature specified by ASME code is 1040 ° C + the minimum tempering temperature is 730 ° C.

Welding

SA213 T92 steel has good welding performance. Preheating temperature ≥100 ℃ can suppress welding cracks, indicating that it has excellent crack resistance. Tungsten inert gas shielded welding (TIG), manual arc welding and submerged arc welding can be used. The welding wire is MTS-616 and the electrode MTS-616. The preheating temperature and layer temperature are controlled at 200-350 ℃.

ASTM A213 ASME SA-213 TP304H stainless steel pipe is mainly used to manufacture the high temperature superheater, high temperature reheater, high temperature section of platen superheater and various high temperature and high pressure resist.

SA-213 TP304H is an austenitic stainless steel with more Cr and Ni elements, and 1Cr18Ni9 in GB5310-95 in China is similar to this steel. The steel has good structure stability, high endurance strength, oxidation resistance, and good processing properties such as elbow pipe and welding process. However, it is more sensitive to intergranular corrosion and stress corrosion, and it is easy to produce work hardening due to more alloy elements, which makes machining difficult; it has high thermal expansion coefficient and poor thermal conductivity.

Standard: ASTM A213, ASME SA213

Equivalent Standards: EN 10216-5, DIN 17458, GOST 9941-81, GOST 9940-81

ASTM A213/A213M specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes. The tubing sizes and thicknesses usually furnished to ASTM A213/A213M specification are 1⁄8 in. [3.2 mm] in inside diameter to 5 in.[127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in minimum wall thickness or, if specified in the order, average wall thickness.

Material: TP304H, S30409

Equivalent Material: 08Ch18N10, X5CrNi18-10, 1.4301, 07Cr19Ni10, X7CrNi18-9, X6CrNi18-10, SUS 304H TB

Manufacture: tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified.

Heat Treatment: solution treatment.

Chemistry Composition of ASTM A213 ASME SA-213 TP304H

| C, % | Si, % | Mn, % | P, % | S, % | Cr, % | Ni, % |

| 0.04-0.10 | 1.00 max | 2.00 max | 0.045 max | 0.030 max | 18.0-20.0 | 8.0-11.0 |

Mechanical Properties of ASTM A213 ASME SA-213 TP304H

| Tensile Strength , MPa | Yield Strength, MPa | Elongation, % | Hardness, HB |

| 515 min | 205 min | 35 min | 192 max |

Outside Diameter & Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤190.5 | +0.4/-1.2 | |

| 190.5<OD≤228.6 | +0.4/-1.6 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, mm |

| OD<25.4 | ±0.10 | |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤190.5 | +0.38/-0.64 | |

| 190.5<OD≤228.6 | +0.38/-1.14 |

Wall thickness & Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, % |

| OD≤38.1 | +20/-0 | |

| OD>38.1 | +22/-0 |

Inspection & Test:

Chemistry composition,

Tensile test,

Hardeness test,

Flattening test,

Flaring test,

NDT,

Surface inspection and dimension check.

ASTM A213 ASME SA-213 TP304H welding material selection

The welding performance is good, and the manual welding rod uses o102, o107, o132 or e308-15 (American brand); the argon arc welding wire uses h0cr19ni9 or er-308; if it is welded with ferritic materials, it is recommended to use ernicr3 or enicrfe-3 welding wire specified in ASME standard. Solution treatment after welding can improve the thermal strength and intergranular corrosion resistance of the welding head.

Application of ASTM A213 ASME SA-213 TP304H Stainless Steel Tubes

Applicable conditions: ASTM A213 ASME SA-213 TP304H stainless steel pipe is mainly used to manufacture the high temperature superheater, high temperature reheater, high temperature section of platen superheater and various high temperature and high pressure resistant pipe fittings of large power generation boiler with subcritical ‘supercritical pressure parameters.

Allowable operating temperature: for pressure parts, the maximum operating temperature can reach 650℃; for anti-oxidation parts, the maximum anti-oxidation operating temperature can reach 850 ℃.

SA213 S30432 (super 304H) steel tube is a new type of 18-8 austenitic stainless steel tubw, which is mainly used to manufacture superheater and reheater of ultra supercritical boiler with metal wall temperature not exceeding 700 ℃.

SA213 S30432 (super 304H) steel is a new type of 18-8 austenitic stainless steel, which is mainly used to manufacture superheater and reheater of ultra supercritical boiler with metal wall temperature not exceeding 700 ℃.

SA213 S30432 (super 304H) steel reduces Mn content on the basis of TP304H, adds 3% Cu, 0.45% Nb and a certain amount of N, which makes the steel produce dispersion precipitation phase and copper rich strengthening phase in service, and copper rich phase together with NBC (n), nbcrn and M23C6 produces excellent precipitation strengthening effect, which greatly improves the allowable stress under service temperature. The allowable stress at 600-650 ℃ is 30% higher than that of TP347H steel. Compared with tp347hfg steel, the steam oxidation resistance of this steel is better than that of tp321h steel. It has been listed in ASME code 2328-1, ASTM A213 and GB 5310-2008 standards, and its grades are S30432 and 10cr18ni9nbcu3bn respectively.

At present, this material is mainly produced by Sumitomo Metal Company of Japan and saskida mannesman company of Germany (formerly DMV company). The product brand of Sumitomo Metal Company is super 304H, and the product brand of saskida mannesman company is DMV30HCu.

Manufacture:Seamless process

Common specifications:38mm*6mm, 45mm*6.7mm, 45mm*9.2mm,

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Threaded

Chemical composition (%) of SA213 S30432 (Super 304H)

| Grade | C | Mn | P | S | Si | Cr |

| SA213 S30432 (Super 304H) | 0.07-0.13 | ≤1.00 | ≤0.040 | ≤0.010 | ≤0.30 | 17.0-19.0 |

| Ni | N | Nb | Al | B | Cu | |

| 7.5-10.5 | 0.05-0.12 | 0.30-0.60 | 0.003-0.030 | 0.001-0.010 | 2.50-3.50 |

Mechanical property of SA213 S30432 (Super 304H)

| Grade | Tensile strength(Mpa) | Yield strength(Mpa) | Elongation(%) | Hardness |

| SA213 S30432 (Super 304H) | ≥590 | ≥235 | ≥35 | ≤95HRB |

Heat treatment and grain size requirements of SA213 S30432 (Super 304H)

| Grade | Type of heat treatment | Austenite / solution treatment temperature, ℃ | Cooling medium | ASTM grain size class number |

| SA213 S30432 (Super 304H) | Solution treatment | ≥1100 | Water cooling or rapid cooling | — |

Selection of SA213 S30432 (super 304H) welding material

SA213 S30432 (super 304H) steel has low carbon content and good weldability. The hot cracking sensitivity test showed that SA213 S30432 (super 304H) had lower hot cracking sensitivity than TP347H. Gas tungsten arc welding (GTAW) or SMAW can be used; the welding materials matching SA213 S30432 (super 304H) have also been developed, namely ා #T-304h and ා #304H, which can be supplied by sumkin welding industries in Japan.

Related knowledge of SA213 S30432 (super 304H) steel pipe

Due to the high steam parameters of the ultra supercritical unit, the power plant and users pay great attention to the oxidation resistance of the steel for high temperature pressure parts. The purpose of shot peening on the inner wall of SA213 S30432 (super 304H) steel pipe is to further improve its oxidation resistance. However, at home and abroad, there is no unified understanding of shot blasting treatment of SA213 S30432 (super 304H) steel pipe inner wall.

Dongfang Boiler Plant (imported technology from BHK company in Japan) and Shanghai Boiler Plant (imported technology from ALSTOM company) proposed that the internal wall of SA213 S30432 (super 304H) steel pipe could be shot blasted according to the user’s requirements; Harbin boiler plant (imported technology from Mitsubishi company in Japan) did not shot blasted SA213 S30432 (super 304H) steel pipe; DMV company clearly proposed that the internal wall shot blasting should be The oxidation resistance of SA213 S30432 (super 304H) steel pipe is very important, and the importance of shot blasting quality is emphasized.

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes.

Tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified.

TP310S (0Cr25Ni20/0Cr25Ni20Si2), heat-resistant stainless steel, commonly known as 310S, also known as 2520 duplex stainless steel, used in the manufacture of high-temperature furnace tubes.

TP310S steel is austenitic chromium-nickel stainless steel with good oxidation resistance and corrosion resistance. Because of the higher percentage of chromium and nickel, TP310S stainless steel has much better creep strength and can continue to operate at high temperatures. It has good High temperature resistance, the highest working temperature is 1200 ℃, and the continuous use temperature is 1150 ℃.

Heat Treatment:

ASTM A213 TP310 stainless steel is an austenitic chromium-nickel stainless steel.

Austenitic Stainless Steels—All austenitic tubes shall be furnished in the heat-treated condition, and shall be heat treated in accordance with the requirements of Table 1.Alternatively, immediately after hot forming, while the tem-perature of the ASTM A213 ASME SA-213 TP310S seamless steel tube is not less than the minimum solution or stabilization treatment temperature specified in Table 1, tubes may be individually quenched in water or rapidly cooled by other means (direct quenched).

The main reason for annealing the TP310 stainless steel tube is to produce a recrystallized fine structure to achieve a uniform grain size and decompose harmful chromium carbide deposits.

Requirements for heat treatment and grain size of ASTM A213 ASME SA-213 TP310S seamless steel tube

| Grade | Heat treatment | Solution treatment temperature,℃ | Cooling medium | ASTM grain size class number |

| SA-213 TP310S | solution treatment. | 1900 [1040] F | Water cooling or rapid cooling | — |

ASTM A213 TP310S Stainless Steel Tube Chemical Composition(%)

| Grade | Chemical Composition(%) | |||||||

| C | Mn | P | S | Si | Cr | Ni | Fe | |

| ASTM A213 TP310S | ≤0.08 | ≤2 | ≤0.045 | ≤0.03 | ≤1.50 | 24-26 | 19-22 | Balance |

ASTM A213 TP310S Stainless Steel Tube Mechanical & Physical Properties

| Grade | Mechanical & Physical Properties | ||||

| Density | Melting Point | Tensile Strength | Yield Strength | Elongation | |

| ASTM A213 TP310S | 8.0 g/cm3 | 1454°C(2650 °F) | Psi-75000,Mpa-515 | Psi-30000,Mpa-205 | 35% |

Outside Diameter & Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤190.5 | +0.4/-1.2 | |

| 190.5<OD≤228.6 | +0.4/-1.6 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, mm |

| OD<25.4 | ±0.10 | |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤190.5 | +0.38/-0.64 | |

| 190.5<OD≤228.6 | +0.38/-1.14 |

Wall thickness & Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, % |

| OD≤38.1 | +20/-0 | |

| OD>38.1 | +22/-0 |

Application of ASTM A213 TP310S Stainless Steel Seamless Tubes

ASTM A213 TP310S stainless steel seamless tube can be used to manufacture furnace tubes, boiler superheaters, and heat exchanger pipe fittings.Usually shows good high temperature strength, creep resistance and corrosion resistance. Therefore, they are widely used in furnace parts in the heat treatment industry. TP310S stainless steel seamless tube is also used in the chemical processing industry to carry hot concentrated acid, ammonia and disulfide in the food processing industry.

Product Features of ASTM A213 TP310S Stainless Steel Seamless Tubes

1) ASTM A213 TP310S stainless steel is austenitic chromium-nickel stainless steel, which has good oxidation resistance, corrosion resistance and high temperature resistance. Because of the higher percentage of chromium and nickel, it has much better creep strength and can be sustained at high temperatures. Operation, has good high temperature resistance. Due to the high content of nickel (Ni) and chromium (Cr), it has good oxidation resistance, corrosion resistance, acid and alkali resistance, and high temperature resistance. High temperature resistant steel pipes are specially used in the manufacture of electric furnace tubes.

2) After increasing the carbon content in austenitic stainless steel, the strength is improved due to its solid solution strengthening effect.

3) The chemical composition characteristics of austenitic stainless steel are based on chromium and nickel with the addition of elements such as molybdenum, tungsten, niobium and titanium. Because its structure is a face-centered cubic structure, it has high strength and creep strength at high temperatures . The melting point is 1470℃, and it starts to soften at 800℃, and the allowable stress continues to decrease.

4) When HNO3≦70%, the corrosion resistance of stainless steel is mainly determined by the amount of chromium in the steel. In higher concentrations of nitric acid, although the amount of chromium in steel also plays a role, the content of impurities (Si, P, S, etc.) in the steel also has an important effect. TP310S steel has low carbon content and high chromium content, and its impurity content is strictly controlled. Therefore, in nitric acid with a concentration of ≦80%, its corrosion resistance is far better than 18-8 (00Cr18Ni10) and high-silicon stainless steel (00Cr18Ni15Si4). Only when the acid concentration is ≧85%, high silicon stainless steel can show its superiority.

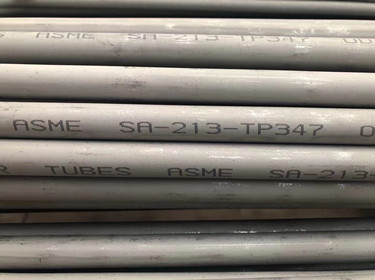

ASTM A213 ASME SA-213 TP347 stainless steel pipe is austenitic stainless acid-resistant steel, widely used in aviation, petrochemical, food, paper and other industries, such as aero-engine exhaust manifolds and branch pipes, turbo compressor hot gas pipes and Equipment and accessories that work under the condition of small load and temperature not exceeding 850℃.

Standard: ASTM A213, ASME SA213

Equivalent Standards: EN 10216-5, DIN 17458, GOST 9941-81, GOST 9940-81

ASTM A213/ASME SA213

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

Materials and Manufacture

Manufacture and Condition—Tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified.

Heat Treatment:

TP347 Stainless Steel Tubes are Austenitic Stainless Steels—All austenitic tubes shall be furnished in the heat-treated condition, and shall be heat treated in accordance with the requirements of Table 1

Heat Treatment and Grain Size of SA213 TP347 Seamless Steel Tube (Table 1)

| Grade | Heat treatment | Solution treatment temperature,℃ | Cooling medium | ASTM grain size class number |

| TP347/S34700 | solution treatment. | 1900 [1040] | Water cooling or rapid cooling | — |

Chemistry Composition of ASTM A213 ASME SA-213 TP347

| C, % | Si, % | Mn, % | P, % | S, % | Cr, % | Ni, % | Nb, % |

| 0.08 max | 1.00 max | 2.00 max | 0.045 max | 0.030 max | 17.0-20.0 | 9.0-13.0 | 10*C-1.1 |

Mechanical Properties of ASTM A213 ASME SA-213 TP347

| Grade | Tensile Strength , MPa | Yield Strength, MPa | Elongation, % | Hardness, HB |

| TP347/S34700 | 515 min | 205 min | 35 min | 192 max |

Physical constants of TP347 stainless steel tube

Melting point: 1398-1427℃

Density: 7.9g/cm3

Specific heat capacity: 500J (kg.K)

Modulus of elasticity: 196GPa at 20℃, 186GPa at 200℃, 177GPa at 400℃, 167GPa at 500℃, 167GPa at 600℃

Specific resistance: 0.75nN.m

Outside Diameter & Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤190.5 | +0.4/-1.2 | |

| 190.5<OD≤228.6 | +0.4/-1.6 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, mm |

| OD<25.4 | ±0.10 | |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤190.5 | +0.38/-0.64 | |

| 190.5<OD≤228.6 | +0.38/-1.14 |

Wall thickness & Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, % |

| OD≤38.1 | +20/-0 | |

| OD>38.1 | +22/-0 |

Inspection & Test:

Chemistry composition

Tensile test

Hardeness test

Flattening test

Flaring test

NDT(Hydrostatic or Nondestructive Electric Test)

Surface inspection and dimension check

Surface Condition

ASTM A213 ASME SA-213 TP347 Stainless steel tubes shall be pickled free of scale.

When bright annealing is used, pickling is not necessary.

Any special finish requirement shall be subject to agreement between the supplier and the purchaser.

ASTM A213 ASME SA-213 TP347 Stainless Steel Tube Corrosion Resistance:

TP347 stainless steel pipe is characterized by good resistance to intergranular corrosion, and has good corrosion resistance in acid, alkali, salt and other solutions.

Intergranular corrosion: Tested by copper sulfate plus sulfuric acid plus copper chips method (T method), copper sulfate plus sulfuric acid method (L method) and 65% HNO3 method (X method).

Oxidation resistance: In the air at 750-800 ℃, this steel has stable oxidation resistance.

TP347Steel Can be welded with ER347 wire.

ASTM A213 ASME SA-213 TP347H Seamless Steel Tubes can be used in high temperature and high pressure environment, with the maximum operating temperature of 650 ℃ for pressure parts and 850 ℃ for oxidation resistant parts.

ASTM A213 ASME SA-213 TP347H Seamless Steel Tubes contains NB-Cr-Ni austenitic stainless steel. Because of the stable element Nb, it has good intergranular corrosion resistance, high endurance strength and oxidation resistance, as well as good technological properties such as bending and welding. Its comprehensive performance is better than ASTM A213 ASME SA-213 TP304H.

Standard: ASTM A213, ASME SA213

Equivalent Standards: EN 10216-5, DIN 17458, GOST 9941-81, GOST 9940-81

ASTM A213/ASME SA213

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

Material: TP347H, S34709

Equivalent Material: 07Cr18Ni11Nb, X7CrNiNb18-10, SUS 347H TB

ASTM A213 ASME SA-213 TP347H Stainless Steel Tubes Quick Details

Country/Region: China

Product Name:ASTM A213 ASME SA-213 TP347H Stainless Steel Tubes

Specifications: 57mm*8mm; 60mm*9mm; 45mm*11mm, 51mm*12mm etc.

Package:Standard export package,suit for all kinds of transport, or as required

Manufacture: tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified.

Chemistry Composition of ASTM A213 ASME SA-213 TP347H

| C, % | Si, % | Mn, % | P, % | S, % | Cr, % | Ni, % | Nb, % |

| 0.04-0.10 | 1.00 max | 2.00 max | 0.045 max | 0.030 max | 17.0-19.0 | 9.0-13.0 | 8*C-1.1 |

Mechanical Properties of ASTM A213 ASME SA-213 TP347H

| Tensile Strength , MPa | Yield Strength, MPa | Elongation, % | Hardness, HB |

| 515 min | 205 min | 35 min | 192 max |

Outside Diameter & Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤190.5 | +0.4/-1.2 | |

| 190.5<OD≤228.6 | +0.4/-1.6 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, mm |

| OD<25.4 | ±0.10 | |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤190.5 | +0.38/-0.64 | |

| 190.5<OD≤228.6 | +0.38/-1.14 |

Wall thickness & Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, % |

| OD≤38.1 | +20/-0 | |

| OD>38.1 | +22/-0 |

| Grade | Heat treatment | Solution treatment temperature,℃ | Cooling medium | ASTM grain size class number |

| SA-347H | solution treatment. | Cold working(1100℃) Hot working(1050℃) | Water cooling or rapid cooling | 7 |

Inspection & Test:

Chemistry composition,

Tensile test,

Hardeness test,

Flattening test,

Flaring test,

NDT,

Surface inspection and dimension check.

Application of sa-213 TP347H seamless steel pipe

Allowable service temperature:A213, SA-213 TP347H seamless steel pipe can be used in high temperature and high pressure environment, with the maximum operating temperature of 650℃ for pressure parts and 850℃ for oxidation resistant parts.

Applicable conditions: A213, SA-213 TP347H stainless steel pipe is mainly used for making high temperature superheater, high temperature reheater, high temperature section of platen superheater and various high temperature and high pressure resistant pipe fittings and other components on large power generation boiler with subcritical and supercritical pressure parameters.

Use guide:

The sa-213tp347h material used in the boiler is austenitic stainless steel with crystallographic structure. It is specially believed in the industry that the service temperature of TP347H material can reach more than 650 ° C, and the high temperature oxidation resistance temperature of the support is only 595 ° C. Therefore, after sa-213tp347h is widely used in supercritical units, the oxide skin produced in sa-213tp347h pipe will fall off, which is very easy to cause tube plugging and tube explosion. It is suggested that sa-213tp347hfg inner wall shot peening (sb) can be upgraded to fine grain.

Selection of A213, SA-213 TP347H welding material

The welding performance is good (the welding joint can pass the l-method intergranular corrosion test). When welding the same kind of steel, the manual welding electrode shall be ao 102, Ao 107, Ao 132 or e308-15 (American brand); the argon arc welding wire shall be er-347; if the welding is carried out with different kinds of steel with ferritic materials, the welding wire or electrode of ernicr3 or enicrfe-3 type specified in ASME standard is recommended. After welding, the boiler pipe shall be subject to solution treatment at 1180 ℃ for 30 minutes.

ASME SA213 TP347HFG steel tubes are mainly used to manufacture high temperature superheater, high temperature reheater.

TP347HFG is a chromium nickel niobium austenitic stainless steel with the same composition as TP347H, but with different processing technology.

Sumitomo Japan has improved two problems of TP347H (one is that the smoke and steam side of TP347H will produce oxide layer peeling off under the action of thermal cycle, and then block at the elbow, resulting in overheating and failure; the other is that the peeled oxide will be brought into the turbine, resulting in serious erosion of the turbine). The mechanism of dissolution and precipitation of fine niobium carbide (NBC) is adopted The new heat treatment process with higher solution treatment temperature makes the grain of TP347H greatly refined. The mechanical properties at room temperature and high temperature are basically the same as those of TP347H. Because the steel is niobium stable austenitic steel, and the grain is obviously refined, the endurance strength is about 20% higher than the ASME code value, the welding performance and fatigue performance are much better than the conventional TP347H steel pipe, and it has good intergranular corrosion resistance, good structure stability, more excellent oxidation resistance and peeling performance, in addition, it also has good bending performance; its comprehensive performance is obvious Better than TP347H. High temperature corrosion resistance of 18-8 stainless steel is the best. In recent years, the steel has been approved by ASME code case 2159 and listed in ASME SA213, named TP347HFG.

Manufacture:Seamless process

Common specifications:50.8mm*10.8mm, 45mm*7.5mm, 70mm*8mm,

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Threaded

Application of ASTM A213 ASME SA213 TP347HFG Seamless Steel Tubes

Like TP347H, ASME SA213 TP347HFG steel tubes are mainly used to manufacture high temperature superheater, high temperature reheater, high temperature section of platen superheater and various high temperature and high pressure resistant pipe fittings of large-scale power generation boiler with supercritical pressure parameters. However, for pressure bearing parts, the maximum working temperature should be higher. Because its comprehensive performance is much better than TP347H, it should be widely used in the future Use.

TP347HFG steel was used in the superheater and reheater materials of the first 700MW, 22.7mpa, 566 / 566 / 566 ℃ ultra supercritical boiler of Chubu Electric Power Co. ‘s Kawagoe power stage in Japan in 1989.

Chemical composition (%)

| Standard | C | Mn | Si | P | S | Cr | Ni |