Boiler Tube

Finned Tube For Heat Exchanger

L Type Finned Tube is a finned tube made of aluminum fin tape or copper fin tape folded into an L-shaped spiral under tension and wrapped tightly around the outer surface of the base tube.

The tension in the fin strips of the L Type Finned Tube wraps around the tube, causing the fin feet to press forcefully against the tube, holding the fins firmly in place. L Type Finned Tube is usually used in air coolers in petrochemical, power, paper, tobacco, building heating and other industries as well as heat exchangers in power plants (electricity, nuclear, thermal and geothermal power plants), the maximum operating temperature can reach 230°C.

L Type Finned Tube for Heat Exchanger Quick Details:

Fin type: Solid plain

Fin Tube Type:L Type

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

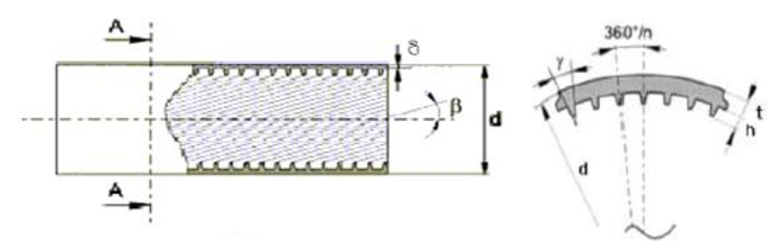

The case of “L” type tension winding type.

Common Specifications of L Type Finned Tube for Heat Exchanger

| All dimensions are in Inches and specification upon your requests | |||

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch |

| 5/8 | 3/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/2 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

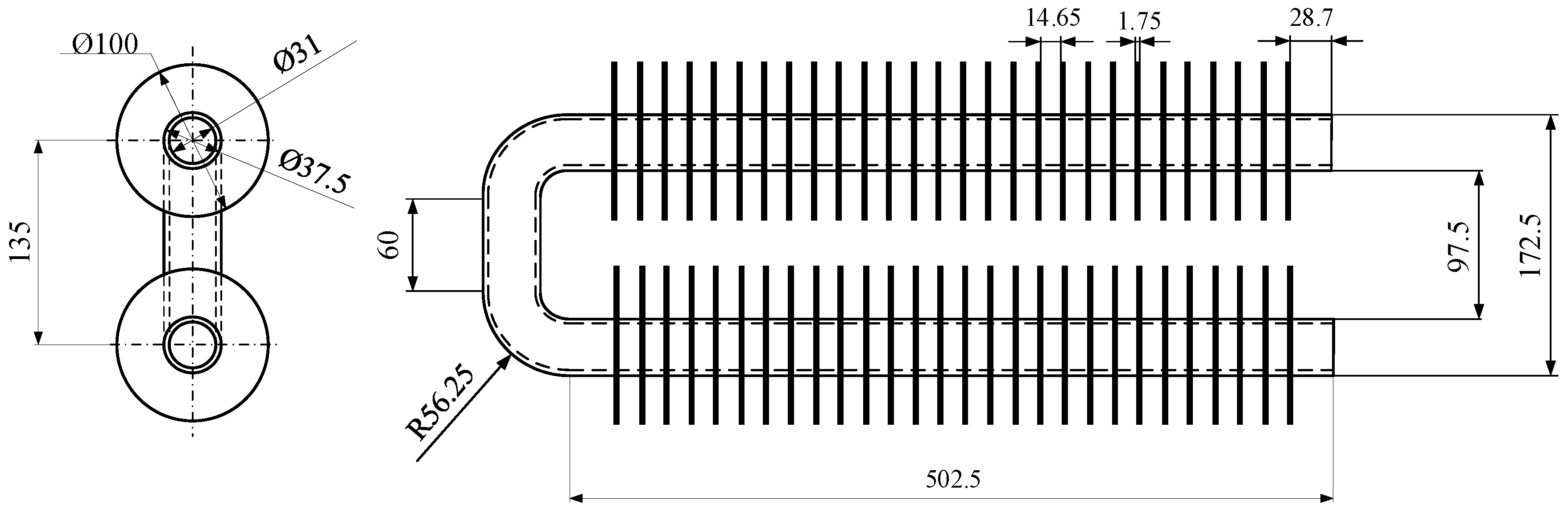

Example:

Manufacturing Process:

Fin strips (usually aluminum and copper) are folded into an L shape and wound under tension on the surface of the base tube. The feet of the fins are connected together and cover the surface of the fins.

L Finned Tube is combined with two different materials

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

| Core Tube Material | |

| Carbon Steel Tubes | A179, A192, SA210 Gr A1/C, A106 Gr B, A333 Gr3 Gr6 Gr8, A334 Gr3 Gr6 Gr8, 09CrCuSb, DIN 17175 St35.8 St45.8, EN 10216 P195 P235 P265, GB/T3087 Gr10 Gr20, GB/T5310 20G 20MnG, |

| Alloy Steel Tubes | A209 T1 T1a,A213 T2 T5 T9 T11 T12 T22 T91,A335 P2 P5 P9 P11 P12 P22 P91,EN 10216-2 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4 |

| Stainless Steel Tubes | TP304/304L, TP316/TP316L TP310/310S TP347/TP347H |

| Copper Tubes | UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10 |

| Titanium Tubes | B338 Gr 2 |

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Quality Control

Inspection and Tests Performed

Chemical Composition inspection,

Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test), S

surface and Dimension Test,

No-destructive Test,

Hydrostatic Test.

Delivery conditions

The tube ends are square cut without burrs, the inside is dry and blown clean, and the ends of the L-shaped tension wound finned tube are coated with varnish on the outside.

Acceptance Criteria

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

Features of L Type Finned Tube

1. The trapezoidal section formed by the calendering of L Type Finned Tube for heat exchanger is consistent with the distribution of heat flow density, the tubes are tightly combined, and the thermal efficiency is high, which eliminates the contact heat caused by the gap between the tubes and the finned tube. resistance, the fin spacing is uniform, and the heat transfer performance is good.

2. The tube can withstand temperatures up to 150°C and there is no risk of atmospheric corrosion or thermal stress.

3. The L-type finned tube provides the contact area between the fin strip and the surface of the tube to protect the tube wall from atmospheric corrosion.

4. This L TYPE design is much more economical than LL, KL or even G-embedded types.

5. Maximum operating temperature: 230°C

Application of L Type Finned Tube

1. Highly corrosive systems (condenser, evaporator, desalination, fertilization, urea system, ammonia, gas, corrosive acid);

2. Air coolers in petrochemical, electric power, paper, tobacco, building heating and other industries;

3. Air heaters and air heaters for spray drying systems such as vegetable protein powder and starch in the food industry;

4. Heat exchanger installations in power plants (electrical, nuclear, thermal and geothermal power plants).

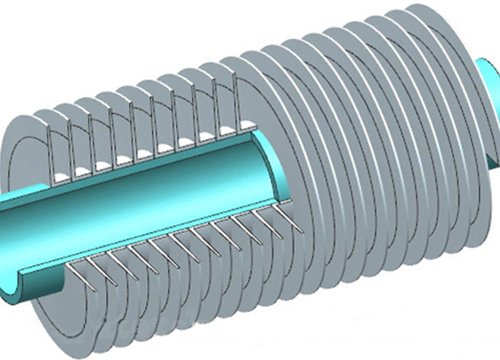

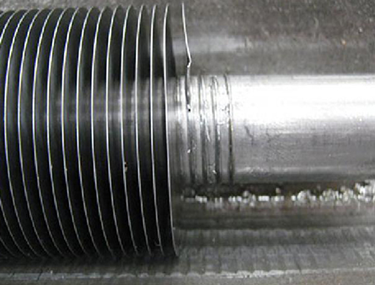

G Type Embedded Finned Tube is that the fin strip is tension wound and placed in the groove cut into the tube with appr, 0.4mm groove depth, then the bottom of the fin is guided into the groove and backfilled with base tube Firmly, finally lock the fins in place by rolling the grooves enclosed in the bottom of the fins. The maximum operating temperature of G Type Embedded Finned Tube can reach 400°C.

G Type Embedded Finned Tube Quick Details:

Core tube material:

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L/316Ti, A789 S31803/S2205

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

Fin material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Fin type: Solid plain

Fin Tube Type: G Type Embedded

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

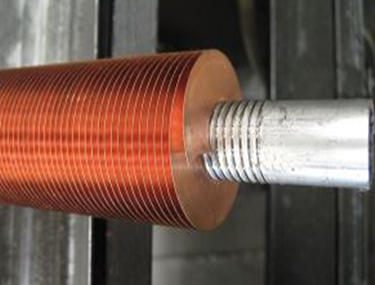

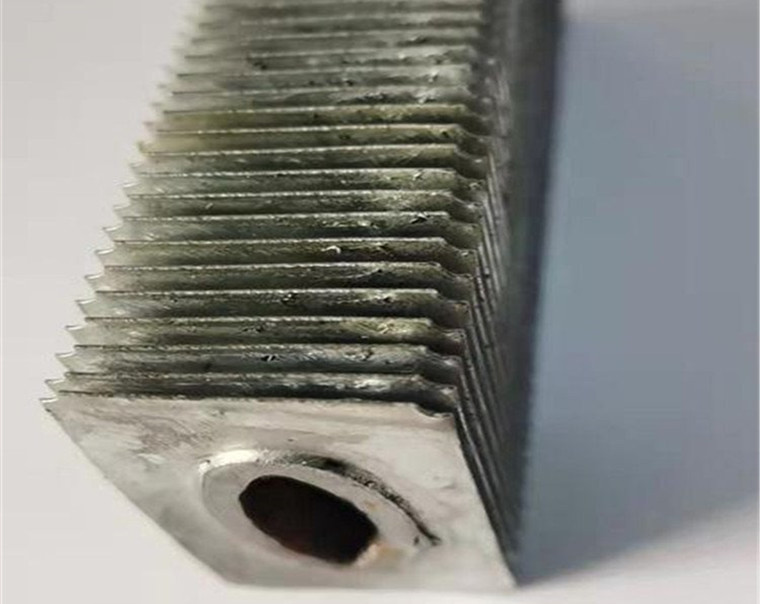

The case of G Type Embedded Finned Tube

Common Specifications of G Type Embedded Finned Tube

| All dimensions are in Inches and specification upon your requests | |||

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch |

| 5/8 | 3/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/2 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

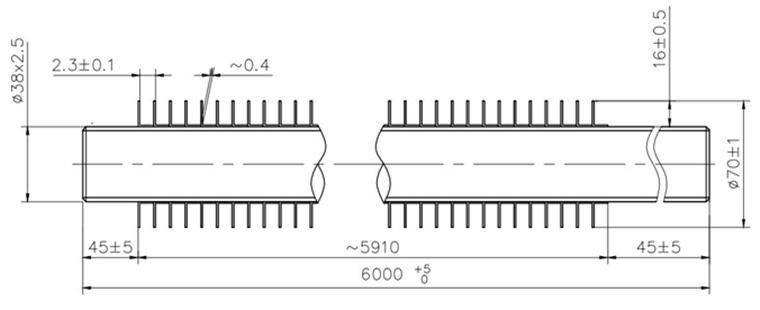

We can customize The case of G Type Embedded Finned Tube according to your drawings

Example:

Manufacturing Process:

G Type Embedded Finned Tube is that the fin strip is tension wound and placed in the groove cut into the tube with appr, 0.4mm groove depth, then the bottom of the fin is guided into the groove and backfilled with base tube Firmly, finally lock the fins in place by rolling the grooves enclosed in the bottom of the fins.

G Type Embedded Finned Tube is combined with two different materials

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L/316Ti, A789 S31803/S2205

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

Fin material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Quality Control for G Type Embedded Finned Tube

Inspection and Tests Performed

Chemical Composition inspection,

Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test),

Surface and Dimension Test,

No-destructive Test,

Hydrostatic Test.

Delivery condition:

Tube ends are square cut, free burrs, internally dried and air blown clean, externally coated with varnish at both ends of G-Fin Embedded Finned Tube.

Acceptance Criteria

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

Features of KL Type Finned Tube for Heat Exchanger

1. High heat transfer performance and small contact thermal resistance.

2. The contact area between the fin and the tube is large, and the fit is tight and reliable.

3. Good resistance to atmospheric corrosion and stable long-term use

4. Can be used for a long time at high temperature

Application of KL Type Finned Tube for Heat Exchanger

●Petroleum, chemical and petrochemical industries

●Natural gas treatment

●Steel industry: blast furnace and converter system

Power generation: exhaust gas from steam turbine condenses, condensate water contact circulation cooling condensate, fossil and nuclear power plants

● Air conditioning (Freon, ammonia, propane)

●Waste incineration equipment

●Compressor cooler, etc.

Maximum operating temperature of KL Type Finned Tube up to 400°C

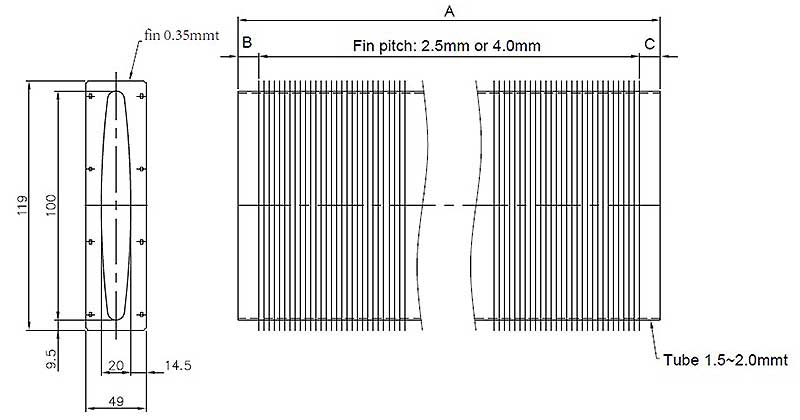

Steel-Aluminum Extruded Type Finned Tube

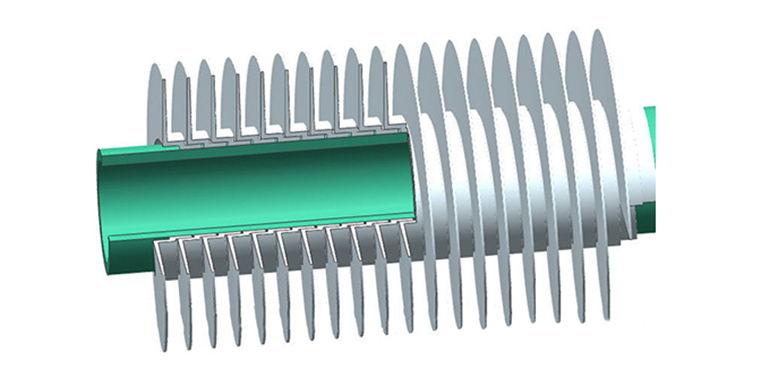

The processing technology of steel-aluminum Extruded Type Finned Tube is to first process aluminum tube and steel tube into bimetallic composite tube, and then form fins after mechanical cold rolling. The aluminum fins are tightly combined into a bimetallic tube finned tube (composite extruded finned tube)

Steel-aluminum rolled finned tubes are integrally rolled from aluminum tubes, and have the characteristics of no contact thermal resistance, high strength, thermal shock resistance and mechanical shock resistance, good thermal performance, and a considerable expansion heat transfer surface. This finned tube heat exchanger is in front of the tube or around the plate.

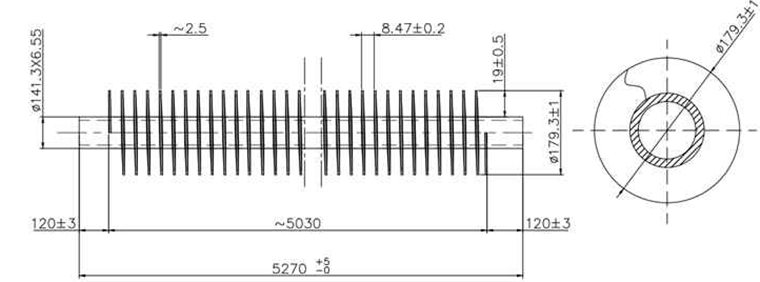

Steel-Aluminum Extruded Type Finned Tube Quick Details:

Core tube material:

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L/316Ti, A789 S31803/S2205

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

Fin material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

Fin type: Solid plain

Fin Tube Type: G Type Embedded

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

The case of Steel-Aluminum Extruded Type Finned Tube

Common Specifications of Steel-Aluminum Extruded Type Finned Tube

| All dimensions are in Inches and specification upon your requests | |||

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch(Density) |

| 5/8 | 3/8,1/2 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, 11, 12 |

| 1 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, 11 |

| 1 1/4 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, |

| 1 1/2 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, 11 |

| 1 3/4 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10 |

| 2 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10 |

We can customize The case of Steel-Aluminum Extruded Type Finned Tube according to your drawings

Example:

Manufacturing Process:

The processing technology of steel-aluminum cold-rolled finned tube is firstly processed from aluminum tube and steel tube into bimetallic composite tube, and then mechanically cold-rolled to form fins. Using the physical properties of the aluminum tube, a finned tube in which the tube with the steel tube as the core and the cold-rolled aluminum fins are tightly integrated is made.

Fin Type:

Fins are solid flat or serrated into 12, 16 or 24 segments or according to your design.

Finless part

Both end with appr. 10mm~50mm, there is a gap in the middle (no fin part).

Steel-Aluminum Extruded Type Finned Tube with two different materials

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

| Core Tube Material | |

| Carbon Steel Tubes | A179, A192, SA210 Gr A1/C, A106 Gr B, A333 Gr3 Gr6 Gr8, A334 Gr3 Gr6 Gr8, 09CrCuSb, DIN 17175 St35.8 St45.8, EN 10216 P195 P235 P265, GB/T3087 Gr10 Gr20, GB/T5310 20G 20MnG, |

| Alloy Steel Tubes | A209 T1 T1a,A213 T2 T5 T9 T11 T12 T22 T91,A335 P2 P5 P9 P11 P12 P22 P91,EN 10216-2 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4 |

| Stainless Steel Tubes | TP304/304L, TP316/TP316L TP310/310S TP347/TP347H |

| Copper Tubes | UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10 |

| Titanium Tubes | B338 Gr 2 |

Fin material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Quality Control for Steel-Aluminum Extruded Type Finned Tube

Inspection and Tests Performed

Chemical Composition inspection,

Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test),

Surface and Dimension Test,

No-destructive Test,

Hydrostatic Test.

Acceptance Criteria

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

Features of Steel-Aluminum Extruded Type Finned Tube

1. High heat transfer performance and small contact thermal resistance;

2. The contact area between the fin and the tube is large, and the fit is tight and reliable;

3. Good corrosion resistance and stable long-term performance;

4. The fins have good rigidity and are not easily deformed.

Application of Steel-Aluminum Extruded Type Finned Tube

Steel-Aluminum Extruded Type Finned Tube is widely used in steel, petroleum, chemical, machinery, shipbuilding, power station, hospital and food industries.

KL type finned tube is a kind of knurled finned tube. Before winding the fins, knurl patterns on the base tube, or add a blade to the winder, knurl on the base tube, and use the back blade A finned tube made by winding, knurling and winding at the same time.

The KL Type Finned Tube relies on maximum surface contact between the fins and the tube, which is ensured by the tension of the fin strips helically forming around the pre-knurled tube, providing improved bonding and heat transfer. The maximum working temperature of KL Type Finned Tube can reach 250°C, and the maximum working pressure can reach 3.2MPa.

KL Type Finned Tube for Heat Exchanger Quick Details:

Core tube material:

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

4. Titanium: B338 Gr 2

Fin material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Fin type: Solid plain

Fin Tube Type:LL Type

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

The case of “KL” type tension winding type.

Common Specifications of KL Type Finned Tube for Heat Exchanger

| All dimensions are in Inches and specification upon your requests. | |||

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch |

| 5/8 | 3/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/2 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

We can customize KL Type Finned Tube for heat exchanger according to your drawings

Example:

Manufacturing Process:

KL type finned tube is a kind of knurled finned tube. Before winding the fins, knurl patterns on the base tube, or add a blade to the winder, knurl on the base tube, and use the back blade A finned tube made by winding, knurling and winding at the same time.

KL Finned Tube is combined with two different materials

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

| Core Tube Material | |

| Carbon Steel Tubes | A179, A192, SA210 Gr A1/C, A106 Gr B, A333 Gr3 Gr6 Gr8, A334 Gr3 Gr6 Gr8, 09CrCuSb, DIN 17175 St35.8 St45.8, EN 10216 P195 P235 P265, GB/T3087 Gr10 Gr20, GB/T5310 20G 20MnG, |

| Alloy Steel Tubes | A209 T1 T1a,A213 T2 T5 T9 T11 T12 T22 T91,A335 P2 P5 P9 P11 P12 P22 P91,EN 10216-2 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4 |

| Stainless Steel Tubes | TP304/304L, TP316/TP316L TP310/310S TP347/TP347H |

| Copper Tubes | UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10 |

| Titanium Tubes | B338 Gr 2 |

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Quality Control for KL Type Finned Tube for Heat Exchanger

Inspection and Tests Performed

Chemical Composition inspection,

Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test), S

surface and Dimension Test,

No-destructive Test,

Hydrostatic Test.

Delivery conditions

The tube ends are square cut without burrs, the inside is dry and blown clean, and the ends of the LL-shaped tension wound finned tube are coated with varnish on the outside.

Acceptance Criteria

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

Features of KL Type Finned Tube for Heat Exchanger

1. High heat transfer performance and small contact thermal resistance.

2. The contact area between the fin and the tube is large, and the fit is tight and reliable.

3. Good resistance to atmospheric corrosion and stable long-term use

Application of KL Type Finned Tube for Heat Exchanger

KL Type Finned Tube is usually used in condensers and heat exchangers with a maximum operating temperature of 250°C and a maximum operating pressure of 3.2MPa.

Type LL finned tube is a finned tube in which the fin feet are preformed into an LL shape (overlapping LLs) and a strip of aluminum fins or copper fins is applied to the base tube under tension. However, the feet are pre-formed so that one foot overlaps the other, increasing the base tube protection and thermal contact area of the finned tube. LL Type Finned Tube is usually used in steam coils, air pre-heaters., the maximum operating temperature can reach 180 °C.

The “LL” shaped fin design features interlocking fins that are twisted together to prevent movement and separation. The fins protect the entire tube, the smooth flat fins with “LL” shaped fins perpendicular to the surface of the seamless steel tube tube provide very low resistance to air/gas flow and ensure that fouling is kept to a minimum. The bottom of the fin is in contact with the base tube and provides a complete jacket over the length of the fin. Hence the name applies to applications where corrosion is a factor. This LL Type Finned Tube is often used as a replacement for more expensive extruded fins in corrosive environments.

LL Type Finned Tube for Heat Exchanger Quick Details:

Core tube material:

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

4. Titanium: B338 Gr 2

Fin material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Fin type: Solid plain

Fin Tube Type:LL Type

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

The case of “LL” type tension winding type.

Common Specifications of LL Type Finned Tube for Heat Exchanger

| All dimensions are in Inches and specification upon your requests. | |||

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch |

| 5/8 | 3/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/2 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

Example:

Manufacturing Process:

Type LL finned tubes are preformed into LL shape (overlapping LLs) with fin feet and aluminum fin tape or copper fin tape is applied to the base tube under tension. The feet are pre-formed to allow one foot to overlap the other, increasing base tube protection and finned tube thermal contact area.

LL Finned Tube is combined with two different materials

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

| Core Tube Material | |

| Carbon Steel Tubes | A179, A192, SA210 Gr A1/C, A106 Gr B, A333 Gr3 Gr6 Gr8, A334 Gr3 Gr6 Gr8, 09CrCuSb, DIN 17175 St35.8 St45.8, EN 10216 P195 P235 P265, GB/T3087 Gr10 Gr20, GB/T5310 20G 20MnG, |

| Alloy Steel Tubes | A209 T1 T1a,A213 T2 T5 T9 T11 T12 T22 T91,A335 P2 P5 P9 P11 P12 P22 P91,EN 10216-2 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4 |

| Stainless Steel Tubes | TP304/304L, TP316/TP316L TP310/310S TP347/TP347H |

| Copper Tubes | UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10 |

| Titanium Tubes | B338 Gr 2 |

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Quality Control for LL Type Finned Tube for Heat Exchanger

Inspection and Tests Performed

Chemical Composition inspection,

Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test), S

surface and Dimension Test,

No-destructive Test,

Hydrostatic Test.

Delivery conditions

The tube ends are square cut without burrs, the inside is dry and blown clean, and the ends of the LL-shaped tension wound finned tube are coated with varnish on the outside.

Acceptance Criteria

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

Features of LL Type Finned Tube for Heat Exchanger

LL type winding finned tube: On the basis of L type, the fin root completely covers the outer surface of the base tube, which can strengthen the contact surface and increase the heat exchange effect.

Maximum working temperature: 180℃.

Mechanical resistance: poor

Application of LL Type Finned Tube

LL Type Finned Tube is usually used in steam coils, air pre-heaters., the maximum operating temperature can reach 180 °C.

Low-fin (integral) tube is an extruded tube composed of short and low fins, and a high-efficiency heat-exchange tube type in which threaded fins are formed on the outer surface of the heat-exchange tube by rolling. The tube and fin are in the same piece of tube, also known as “N” fin type.

Because Low Finned Tube is an integral tube, there is only one material for the tube and fins

We offer you a wide range of materials and can expand our offering at any time to meet your specific needs in terms of thermal conductivity, mechanical properties or corrosion resistance.

Standard Specification for Low Finned Tubes

Carbon Steel: ASTM A 498

Stainless Steel: ASTM A 1012

Copper and Copper Alloys: ASTM B 359

Titanium and Titanium Alloys: ASTM B 891

Material:

Carbon Steel: A179, A192, SA210 Gr A1/C,

Stainless Steel: SA 213/A 213 TP304/304L, TP316/TP316L/316Ti,

Duplex Stainless Steel: SA 789 S31803/S2205,

Copper and copper alloys SB 111 / B 111 UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10,

Titanium and titanium alloys: SB 338 / B 338 GR1 GR2 GR3 GR5 GR6 GR7 GR9 GR12 GR16 GR17 etc.

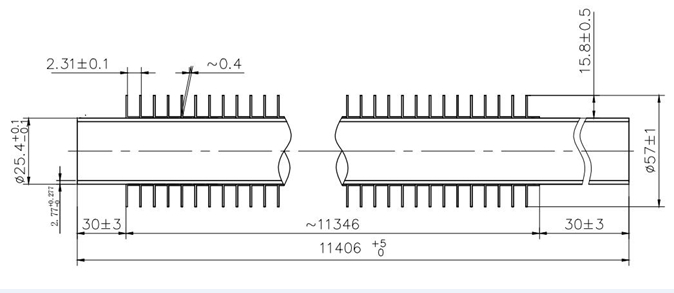

Low Finned Tube Quick Details:

Fin type: Solid plain

Outer diameter (OD): 12.7mm~25.4mm

Tube length: up to 25000mm

Fin height: 1.2mm ~2.77mm

Fin thickness: about 0.3mm

Fin pitch: 30 FPI/28 FPI/26 FPI/36 FPI/43 FPI

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

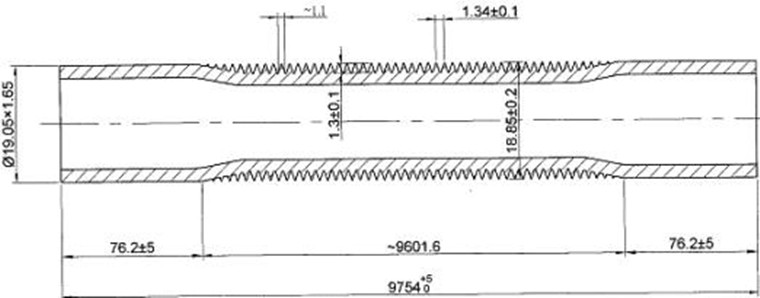

The case of Low Finned Tube

Data sheet of Low Fin Tubes

| Plain tube (mm) | Finned section dimensions (mm) | Ratio | De | |||

| D×t | Tp | dd | dr | di | η | mm |

| 19×2 | 0.8 | 18.8 | 17 | 134 | 2.8 | 17.9 |

| 19×2 | 1 | 18.8 | 16.8 | 13.4 | 2.5 | 17.8 |

| 19×2 | 1.25 | 18.8 | 16.6 | 13 | 2.2 | 17.8 |

| 19×2 | 1.5 | 18.8 | 16.6 | 13 | 2 | 17.7 |

| 19×2 | 2 | 18.8 | 16.4 | 13 | 1.7 | 17.5 |

| 25×2.5 | 0.8 | 24.8 | 23 | 18.8 | 2.8 | 23.9 |

| 25×2.5 | 1 | 24.8 | 22.6 | 18.8 | 2.75 | 23.7 |

| 25×2.5 | 1.25 | 24.8 | 22.3 | 18 | 2.5 | 23.6 |

| 25×2.5 | 1.5 | 24.8 | 22.3 | 18 | 2.2 | 23.5 |

| 25×2.5 | 2 | 24.8 | 22 | 18 | 1.8 | 23.4 |

| 25×2.5 | 2.5 | 24.8 | 22 | 18 | 1.6 | 23.3 |

| D——Outside diameter of plain end section Dof—-Diameter of top fins Dr—–Root diameter of finned section Di—–Inside diameter of finned section T——Wall thickness of plain end section Tp—–Fin pitch De—-Equivalent diameter of finned tube L——Plain tube end length | ||||||

| Please email us for more information. | ||||||

We can provide monolithic low finned tubes with no fin section clearance (min. 5mm) in the middle of the core tube, or bent to the designed bend radius.

Example:

Manufacturing Process:

Low fin (integral) tube is an extruded tube consisting of short low fins, the fins are rolled out from the outer wall of the plain tube by rollers, and the tube and fins are in the same piece of tube.

Delivery conditions:

The tube ends are square cut, free of burrs, dry and blown clean on the inside and varnished on the outside.

Put desiccant in each package for continental shipping.

Quality Test:

The integral low fin tube quality is assured by hydrostatic or pneumatic tests, eddy current tests & MARCO tests in order to verify design specifications.

Acceptance ceritia:

WOLVERINE / HPT / GEWA-K & GEWA-KS

Features of Low Finned Tube

1. The processing cost is low;

2. The low-finned tube is formed by directly rotating the steel tube to form fins, so there is no need to worry about falling off even if it is bent later.

3. Has excellent durability and anti-vibration performance.

4. Increase the external surface area of the bare tube by 2.5-3 times, improve the efficiency of the heat exchanger, and improve the performance of the existing heat exchanger.

5. The reduction in space and weight is very valuable for offshore production or high altitude distillation columns. Low-fin technology can transform large shell and tube heat exchangers into compact heat exchangers

6. It has a wide range of applications and can strengthen the evaporation, condensation, gaseous heat transfer and liquid heat transfer of the medium on the shell side;

Application of Low Finned Tube

As long as the medium on the shell side is relatively clean, free from corrosion and scaling, low finned tubes can be used as heat exchange elements to form a low finned tube type high-efficiency heat exchanger.

Oval rectangular finned tube, oval oval finned tube, oval circular finned tube, helical oval flat tube, oval H-shaped finned tube

Elliptical Finned Tube is an elliptical seamless tube as the base tube, which uses aluminum fin strips or copper fin strips to spirally and tightly wrap around the outer surface of the base tube under tension.

Elliptical Finned Tube is a heat exchange element consisting of a base tube elliptical tube and outer fins.

Spiral Elliptical Flat Tube

EllipticalH-shaped finned tubes

Because Elliptical Finned Tube has superior performance than round finned tube, Elliptical Finned Tube is receiving attention, and Elliptical Finned Tube has been widely used in ethylene, oil refining and other industrial fields. Elliptical Finned Tube is used in heat exchange equipment as a high-efficiency heat exchange element. The flow resistance outside the tube is small and the heat exchange efficiency is high, which makes the heat exchange equipment tend to be compact, lightweight, efficient and miniaturized. Although much research has been done on them, there is still a lot of research work to be done.

Elliptical Finned Tube Quick Details:

KL Type Finned Tube for Heat Exchanger Quick Details:

Core tube material:

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

4. Titanium: B338 Gr 2

Fin material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Fin type: Solid plain

Outer diameter (OD): According to customer’s request

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

Common Specifications of Elliptical Finned Tube

| General Descriptions of Studded tubes | Popular Specifications we make |

| Tube OD(mm) | OD38mm~OD219mm |

| Tube Wall Thickness(mm) | 4mm~15mm |

| Tube Length(mm) | 16,000mm Max. |

| Studs OD(mm) | OD6mm~OD16mm |

| Studs Height(mm) | 10mm~45mm |

We can customize Elliptical Finned Tube according to your drawings

Example:

Manufacturing Process:

An oval seamless tube is used as the base tube, and the finned tube is spirally wound with aluminum fin tape or copper fin tape under tension and tightly wound on the outer surface of the base tube.

Elliptical Finned Tube is combined with two different materials

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

| Core Tube Material | |

| Carbon Steel Tubes | A179, A192, SA210 Gr A1/C, A106 Gr B, A333 Gr3 Gr6 Gr8, A334 Gr3 Gr6 Gr8, 09CrCuSb, DIN 17175 St35.8 St45.8, EN 10216 P195 P235 P265, GB/T3087 Gr10 Gr20, GB/T5310 20G 20MnG, |

| Alloy Steel Tubes | A209 T1 T1a,A213 T2 T5 T9 T11 T12 T22 T91,A335 P2 P5 P9 P11 P12 P22 P91,EN 10216-2 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4 |

| Stainless Steel Tubes | TP304/304L, TP316/TP316L TP310/310S TP347/TP347H |

| Copper Tubes | UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10 |

| Titanium Tubes | B338 Gr 2 |

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Quality Control

Inspection and Tests Performed

Chemical Composition inspection,

Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test), S

surface and Dimension Test,

No-destructive Test,

Hydrostatic Test.

Delivery conditions

The tube ends are square cut without burrs, the inside is dry and blown clean, and the ends of the L-shaped tension wound finned tube are coated with varnish on the outside.

Acceptance Criteria

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

Features of Elliptical Finned Tube

(1) Compared with the round tube finned tube, the Elliptical Finned Tube is easier to achieve a compact arrangement, which reduces the overall volume of the entire heat exchanger, thereby reducing the footprint.

(2) Due to the shape characteristics of the Elliptical Finned Tube, the air-side resistance is small, and the heat transfer coefficient between the fluids increases; the thermal resistance in the tube is relatively small, which increases the heat transfer of the fluid in the tube.

(3) The heat transfer area of the Elliptical Finned Tube is larger than that of the circular tube of the same cross-sectional area, because the heat transfer periphery of the elliptical tube is relatively long under the same cross-sectional area.

(4) Rectangular steel fins are the most commonly used in Elliptical Finned Tubes, which have high strength, and the base tube is not suitable for frost cracking in winter and has a long service life.

(5) Since the Elliptical Finned Tube can be arranged more compactly, the front row tube has a greater impact on the rear row. The fin spacing of the rear row tube can be increased to reduce the flow resistance outside the tube, but the number of tube rows should not be too large.

Application of Elliptical Finned Tube

Application: The convection chamber of the heating furnace in the petrochemical industry is used in the Elliptical Finned Tube

, which can increase the heat transfer coefficient on the gas side, and the area of the elliptical tube is 2 to 3 times that of the straight tube. Due to the application of Elliptical Finned Tube, in the design of this case, the same radiation intensity can get the same thermal intensity.

It uses winding technology, ranging from stable, segmented combination and firm, to surface galvanized and nickel-based brazing, depending on the application. has a high heat transfer efficiency, while the wind side has a small

Compared with the section of the circular tube, the heat transfer coefficient can be increased by 25%, and the air resistance can be reduced by 15%-25%.

Stud Finned Tube, also known as nail head Finned Tube (also known as needle-shaped tube, nail-shaped ribbed tube), adopts a square or hexagonal arrangement and is equally divided into cylindrical needles welded on the surface of the heat exchange tube. The square or hexagonal reinforced heat exchange nail head tube is assembled and welded to form a high-efficiency and energy-saving needle tube heat exchange tube group.

Because the Stud Finned Tube pin rib is a cantilever structure with a compact structure, under the impact of the airflow, the pin rib vibrates, making it difficult for soot to accumulate; coupled with the strong turbulent scouring of the flue gas, the Stud Finned Tube heat exchange The element has high heat transfer efficiency and strong self-cleaning ability.

Stud Finned Tube Quick Details:

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

4. Titanium: B338 Gr 2

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Fin type: U fins,perforated,twist…

Type of Studs: Cylindrical or elliptical

Tube outer diameter: up to 219 mm.

Tube thickness: 4mm~15mm

Tube length: up to 16 meters.

Stud outer diameter: OD6mm~OD16mm

Stud Height: Min. 10mm.

Surface Protection: Oil immersed, black coated or varnished.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

The case of Stud Finned Tube

Common Specifications of LL Type Finned Tube for Heat Exchanger

| General Descriptions of Studded tubes | Popular Specifications we make |

| Tube OD(mm) | OD38mm~OD219mm |

| Tube Wall Thickness(mm) | 4mm~15mm |

| Tube Length(mm) | 16,000mm Max. |

| Studs OD(mm) | OD6mm~OD16mm |

| Studs Height(mm) | 10mm~45mm |

We can customize Stud Finned Tube according to your drawings

Example:

Manufacturing Process:

Stud Finned Tube, also known as nail head Finned Tube (also known as needle tube, nail ribbed tube) adopts a square or hexagonal arrangement and equal parts to fully automatically weld the stud to the heat exchange tube by resistance welding.

Stud Finned Tubes is combined with two different materials

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

| Carbon Steel Tubes | A179, A192, SA210 Gr A1/C, A106 Gr B, A333 Gr3 Gr6 Gr8, A334 Gr3 Gr6 Gr8, 09CrCuSb, DIN 17175 St35.8 St45.8, EN 10216 P195 P235 P265, GB/T3087 Gr10 Gr20, GB/T5310 20G 20MnG, |

| Alloy Steel Tubes | A209 T1 T1a,A213 T2 T5 T9 T11 T12 T22 T91,A335 P2 P5 P9 P11 P12 P22 P91,EN 10216-2 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4 |

| Stainless Steel Tubes | TP304/304L, TP316/TP316L TP310/310S TP347/TP347H |

| Copper Tubes | UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10 |

| Titanium Tubes | B338 Gr 2 |

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Delivery conditions

The tube ends are square cut, free of burrs, the inside is dry and blown clean, and the two ends of the extruded bimetallic finned tube are coated with varnish on the outside.

Acceptance Criteria

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

Features of Stud Finned Tubes

The structure of Stud Finned Tubes is compact. Under the impact of the airflow, the needle ribs vibrate, making it difficult for soot to accumulate; coupled with the strong turbulent scouring of the flue gas, the Stud Finned Tube heat exchange element has high heat transfer efficiency and has Strong self-cleaning ability.

Due to the high rigidity of Stud Finned Tubes, studded tubes can be used even under extreme temperature and pressure conditions.

Application

The nail head tube group is especially suitable for compact waste heat boilers, oil-fired, gas-fired boilers and oil heaters. Under the same heat exchange, its weight and external dimensions are greatly reduced. The anti-fouling performance of the nail head tube group is greatly improved compared with other conventional enhanced heat transfer boiler tubes. In the case of low flue gas temperature, the nail head tube can still recover waste heat economically, and has broad application prospects in heat exchange and energy saving projects.

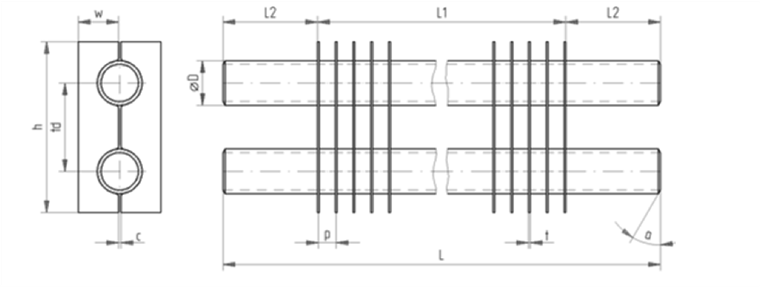

H Finned Tube is divided into single H Finned Tube and Twin H Finned Tube (HH or Doule H finned tube), also known as Rectangular Finned Tubes. H Finned Tube is made by welding square or rectangular H fins to a steel base tube.

Twin H Finned Tube (HH or Doule H Finned Tube)

The fins are divided into two symmetrical halves, the tube wall is pressed from both sides, and the tube wall is welded by resistance welding, leaving a certain gap in the middle; two round tubes can share a set of fins, called Twin H Finned Tube

Single H Finned Tube

The fin is divided into two symmetrical halves, which press the tube wall from both sides, and are welded to the tube wall by resistance welding, leaving a certain gap in the middle; there is only one round tube in the middle, which is called Single H Finned Tube.

The heat exchanger composed of H-shaped finned tubes is closely arranged, and the tube bundles are arranged in a row.

H Finned Tube Quick Details:

Core tube material:

1. Carbon Steel: A106 / A179 /A192 / A210 etc…

2. Stainless Steel: TP304/304L,TP316/TP316L, TP347 etc…

3. Alloy Steel: P5,T5,P9,T9,T11,T22

Fin Material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Tube OD: 73 mm max.

Tube Length: 18 meters max.

Fin Thickness: 1.5mm ~3.5mm

Fin Pitch: 10mm Min.

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

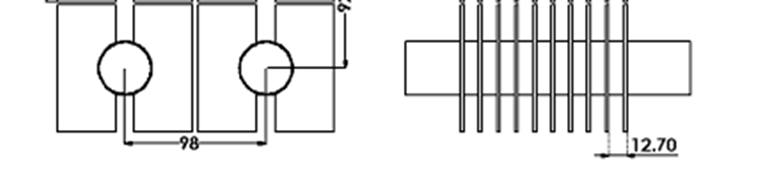

The case of H Finned Tube

Common Specifications of H Finned Tube

| General Descriptions of H-fins | Popular Specifications we make |

| Tube OD(mm) | 25mm to 73mm |

| Tube Wall thickness(mm) | 2.5mm Min. |

| Tube length(mm) | 18000mm Max. |

| Fin thickness(mm) | 1.5mm to 3.5mm |

| Fin pitch(mm) | 10mm Min. |

Example:

Manufacturing Process:

H Finned Tube is made by welding square or rectangular H fins to a steel base tube.

Quality Control for H Finned Tube

The quality of Square or Rectangualr H finned tubes is assured by hydrostatic or aerodynamic testing, eddy current testing and tensile testing to verify the mechanical bond between the inner tube and outer fins

Surface coating

External red oxidized zinc phosphate primer and internal Volatile Corrosion Inhibitor (VCI) in water-soluble tablet form.

Delivery conditions

Tube ends are square cut, free of burrs, dry and blown clean inside, varnished on both ends of square or rectangular finned tubes.

Features of H Finned Tube

maximum. Operating temperature: 300°C

Atmospheric corrosion resistance: OK

Mechanical resistance: good

The influence of the structure of H Finned Tube on ash accumulation and wear: the gap between the two sheets can use the flow of flue gas and scour the ash accumulation, because the flue gas has a higher flow rate at the gap; the tubes are arranged in a row, and the resistance Small wear and tear; H-shaped fins can effectively utilize the flow space and maintain a large fin area and finning ratio; The thickness of the fins can be arbitrarily selected according to the needs of anti-wear; The fins are parallel and independent of each other, without helix angle effect, thus facilitating ash removal.

Application

H Finned Tube is usually used in Economizers, Heat exchangers, Marine boilers.

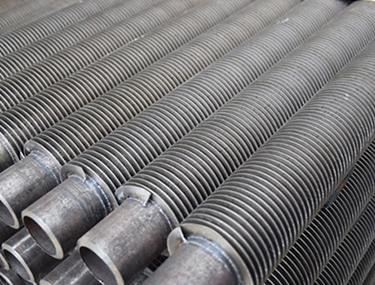

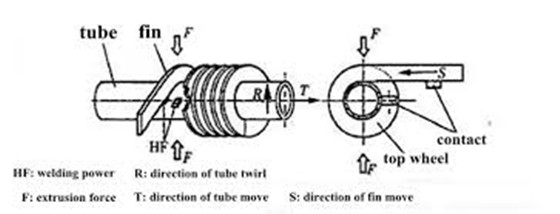

HF Finned Tube is also known as high frequency welded spiral finned tube, high frequency welded spiral finned tube is a tubular high-efficiency heat transfer element with spiral fins. The extended surfaces (fins) can be solid or serrated and have up to tens of times more heat transfer area than a bare tube.

HF Finned Tube is a spiral winding of steel fins, which is continuously welded on the steel pipe by high frequency resistance welding (HFERW). A high-frequency current is introduced into the workpiece, the welding contact surface is melted or semi-melted by resistance heat, and then appropriate pressure is applied to the welding contact surface to complete the welding of the finned tube. This produces a uniform, clean and continuous finned tube combined with no additional welding material for very efficient heat flow and corrosion resistance.

High-frequency welded spiral finned tube is one of the most widely used spiral finned tubes.

HF Finned Tube Quick Details:

Core tube material:

1. Carbon Steel: A106 / A179 /A192 / A210 etc…

2. Stainless Steel: TP304/304L,TP316/TP316L, TP347 etc…

3. Alloy Steel: P5,T5,P9,T9,T11,T22

Fin Material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Tube/Pipe Size 1.00″ to 15.75″ OD

Fin Height 0.3mm to 49.50mm

Fin Segment Width 5/32″ or 5/16″

Fin Thickness 0.8 mm ~ 4.0 mm

Fin Pitch 1 to 20 fins per inch

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

The case of HF Finned Tube

We can customize HF Finned Tube according to your drawings

Example:

Manufacturing Process:

HF Finned Tube is a spiral winding of steel fins, which is continuously welded on the steel pipe by high frequency resistance welding (HFERW). A high-frequency current is introduced into the workpiece, the welding contact surface is melted or semi-melted by resistance heat, and then appropriate pressure is applied to the welding contact surface to complete the welding of the finned tube.

Quality Control for HF Finned Tube

The quality of the HF Finned Tube is assured by hydrostatic or pneumatic testing, eddy current testing and tensile testing to verify the mechanical bond between the inner tube and the outer fins

Delivery conditions

Burr-free, dry and blow-out inside, HF Finned Tube with varnish on both ends.

Features of HF Finned Tube

1. Due to the fast welding speed and strong self-cooling effect of the weldment, not only the heat affected zone is small, but also oxidation is not easy to occur, so the structure and performance of the weld are very good.

2. Anti-corrosion performance, wear-resistant performance, low contact thermal resistance, high stability, and anti-fouling ability.

3. Large heat exchange area.

Application

HF Finned Tube (high frequency welded spiral finned tube) is one of the most widely used spiral finned tubes, and is now widely used in power, metallurgy, waste heat recovery in cement industry, petrochemical industry and other industries.

U Bending Low Finned Tubes are high-efficiency U Bending Low Finned Tubes rolled on the outer surface of U Bending heat exchange tubes to form threaded fins. U Bending Low Finned Tubes can be twisted and bent into various shapes. Shaped, square or serpentine configurations to take advantage of more limited spaces.

The fin pitch size of U Bending Low Finned Tubes needs to be determined according to the surface tension of the liquid and the shear force on the liquid film generated by the flow.

U Bending Low Finned Tube Quick Details:

Core tube material:

1. Carbon Steel: A106 / A179 /A192 / A210 etc…

2. Stainless Steel: TP304/304L,TP316/TP316L, TP347 etc…

3. Alloy Steel: P5,T5,P9,T9,T11,T22

Fin Material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Tube/Pipe Size 1.00″ to 15.75″ OD

Fin Height 0.3mm to 49.50mm

Fin Segment Width 5/32″ or 5/16″

Fin Thickness 0.8 mm ~ 4.0 mm

Fin Pitch 1 to 20 fins per inch

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

The case of U Bending Low Finned Tube

We can customize U Bending Low Finned Tube according to your drawings

Example:

Manufacturing Process:

U Bending Low Finned Tubes are high-efficiency U Bending Low Finned Tubes rolled on the outer surface of U Bending heat exchange tubes to form threaded fins. U Bending Low Finned Tubes can be twisted and bent into various shapes. Shaped, square or serpentine configuration

Quality Control for U Bending Low Finned Tubes

The quality of U Bending Low Finned Tubes is assured by hydrostatic or pneumatic testing, eddy current testing and tensile testing to verify the mechanical bond between the inner tube and outer fins

Delivery conditions

Burr-free, dry and blown on the inside, U Bending Low Finned Tubes are varnished on the outside on both ends.

Features of U Bending Low Finned Tubes

U Bending Low Finned Tubes mainly rely on the outer ribbing of the tube (ribing coefficient is 2~3) to expand the heat transfer area. Compared with the bare tube, it has a larger surface area with the same consumption of metal materials. Intuitively, it is the first time to strengthen heat transfer, but in essence, the increase of heat transfer area brings about the improvement of heat transfer coefficient. The heat transfer effect, the second strengthens the heat transfer. The main factors affecting the heat transfer enhancement of the ribbed surface are the height of the fin, the thickness of the fin, the distance between the fins and the thermal conductivity of the fin material. In addition, since one side of the heat transfer wall is expanded into a fin surface, the convective heat transfer on the smooth side and the thermal conductivity of the base wall all have a certain influence on the total heat transfer.

Application

U Bending Low Finned Tubes are often used in air coolers, process cooling, lube oil cooling, heat exchangers, steam air heaters, economizers, gas compressor waste incinerators, blast furnaces/rotary furnaces, etc.

Serrated Finned Tube is a high-frequency welding production process with high-frequency patented technology. Using high-frequency power supply as a heat source, the steel strip and steel pipe are heated at the same time, so that they can be welded together. It has the characteristics of long life, wide temperature range and high pressure tolerance.

Serrated Finned Tube Quick Details:

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

4. Titanium: B338 Gr 2

Fin type: U fins,perforated,twist…

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Fin Tube Type: Plain Strips

Fin number: 2/ 4/ 8/ 16/ 18/ 32/ 36 piece per row

Number of fins: 16/20/24/32/40

Tube OD: 19mm min.

Tube Length: 18 meters max.

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

The case of Serrated Finned Tube

We can customize Serrated Finned Tube according to your drawings

Example:

Manufacturing Process:

Serrated Finned Tube use high-frequency welding production process, using high-frequency power source as heat source, to heat steel strip and steel pipe at the same time, so that they can be welded together into one

1. U-bends with longitudinal fins and fin coils are available on request.

2. Longitudinal fin types: one piece, standard U-bend, cut and twisted, perforated, etc…

3. The fin channels are welded to the tube in pairs. The fin height, number of fins, and fin thickness can be specified.

4. Fins can be used for OD pipe or NB pipe.

Serrated Finned Tube is combined with two different materials

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

| Carbon Steel Tubes | A179, A192, SA210 Gr A1/C, A106 Gr B, A333 Gr3 Gr6 Gr8, A334 Gr3 Gr6 Gr8, 09CrCuSb, DIN 17175 St35.8 St45.8, EN 10216 P195 P235 P265, GB/T3087 Gr10 Gr20, GB/T5310 20G 20MnG, |

| Alloy Steel Tubes | A209 T1 T1a,A213 T2 T5 T9 T11 T12 T22 T91,A335 P2 P5 P9 P11 P12 P22 P91,EN 10216-2 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4 |

| Stainless Steel Tubes | TP304/304L, TP316/TP316L TP310/310S TP347/TP347H |

| Copper Tubes | UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10 |

| Titanium Tubes | B338 Gr 2 |

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Delivery conditions

The tube ends are square cut without burrs, the inside is dry and blown clean, and the ends of the L-shaped tension wound finned tube are coated with varnish on the outside.

Acceptance Criteria

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

Features of Serrated Finned Tube

1. Simple and economical installation. The maximum length of the sawtooth high-frequency welded spiral finned tube can reach 16 meters, which reduces the number of connection points, makes the installation more economical and quicker, and reduces the probability of water leakage at the connection.

2. Easy to maintain. After the serrated high-frequency welded spiral fin tube is installed, it is basically maintenance-free.

3. High-efficiency, sawtooth high-frequency welding spiral finned tube is full contact welding of fin and steel tube winding, the heat dissipation area is more than 8 times that of the light tube, the interior is smoother, and the internal water flow resistance is small.

4. Long service life, high mechanical strength of fins and pipes, tensile strength of more than 200Mpa, and hot-dip galvanizing treatment inside and outside the pipes.

Application

Serrated Finned Tube is a new, wear-resistant and high-efficiency heat-exchange material. It is a high-efficiency and energy-saving heat-exchange element. It is widely used in waste heat recovery, petrochemical, power station boilers, economizers, passenger cars, industrial and civil building heating and refrigeration. , Medicine drying, wood drying, grain drying systems and other industries.

Crimped Finned Tube, also known as Cold Raised Finned Tube, is to spirally wound crimped fins on the base tube without welding, but spot welding. Root welded or fully tinned non-ferrous tubes and fins.

The fins of the Crimped Finned Tube are crimped, which allows the Crimped Finned Tube to provide higher air side turbulence and heat transfer.

Crimped Finned Tube Quick Details:

Core tube material:

1. Carbon Steel: A106 / A179 /A192 / A210 etc…

2. Stainless Steel: TP304/304L,TP316/TP316L, TP347 etc…

3. Alloy Steel: P5,T5,P9,T9,T11,T22

Fin Material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Tube outer diameter: 12mm Min ~ 50.8mm max.

Tube length: up to 18,000 mm.

Fin height: max. 20 mm.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both exposed ends of the crimp finned tube shall be hot-dip galvanized. .

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

The case of Crimped Finned Tube

S/R Descriptions of Crimped I Type Fin Tube Popular specifications we make

| S/R | Descriptions of Crimped I Type Fin Tube | Popular specifications we make |

| 1 | Tube OD | 5/8” to 3” (15.8 mm to 76.2 mm) |

| 2 | Fin Height | 1/4” to 3/4” or 6.4 mm to 20 mm. |

| 3 | Fin Pitch | 3FPI to 11FPI or 118 FPM to 433 FPM. |

We can customize Crimped Finned Tube according to your drawings

Manufacturing Process:

Crimped Finned Tube is a helically wound crimped fin on the base tube without welding, but spot welding. Root welded or fully tinned non-ferrous tubes and fins.

Quality Control for Crimped Finned Tube

The quality of the Crimped Finned Tube is assured by hydrostatic or pneumatic testing, eddy current testing and tensile testing to verify the mechanical bond between the inner and outer tubes.

Delivery conditions

The tube ends are square cut, free of burrs, dry and blown clean on the inside and varnished on the outside on both ends. Desiccant is also put into each package for continental shipping.

Application

U Bending Low Finned Tubes are widely used in environments with a certain degree of corrosion or cleanliness, such as climate industry, heating, drying and cooling.

Features of Crimped Finned Tube

Uniform pitch, small wrinkle, no dust accumulation

Small contact thermal resistance, strong heat transfer ability

Crimped Finned Tube can be further hot-dip galvanized to protect the surface, and the deposition of zinc also increases the efficiency of the finned tube. Maximum operating temperature 250°C.

Applications Commercial applications for air heating or air cooling up to 130°C to 150°C

Inner Grooved Low Finned Tubesalso known as steam finned tubes, inner finned tubes, low Inner Grooved Low Finned Tubesare ordinary heat exchange tubes that are rolled to form threads on their inner surface, and the fins are removed from the bare tube by rolling rolls The outer wall rolls out. A high-efficiency heat exchange tube type with tubes and fins in the same tube.

Inner Grooved Low Finned Tubes are usually made of copper and are always made with vertical rods for easier installation.

The strengthening effect of this Inner Grooved Low Finned Tubes is outside the tube. The strengthening effect on the medium is reflected in the fact that the threaded fins increase the heat exchange area on the one hand; on the other hand, when the shell-side medium flows through the surface of the threaded pipe, the surface threaded fins have a dividing effect on the laminar flow edge layer and thin the boundary. layer thickness. Moreover, the turbulence formed on the surface is also stronger than that of the light pipe, which further reduces the thickness of the boundary layer. As a result of the combined effect, the tube type has a high heat transfer capacity. When this tube type is used for evaporation, it can increase the number of bubbles formed on the unit surface and improve the boiling heat transfer capacity; when it is used for condensation, the threaded fins are very conducive to the dripping of the condensate at the lower end of the tube, reducing the liquid film. Thin, thermal resistance is reduced, and condensation heat transfer efficiency is improved.

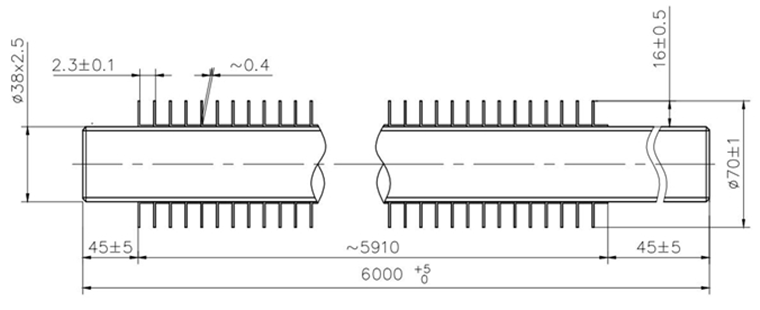

Inner Grooved Low Finned Tubes Quick Details:

Standard: ys/t440, gb/t 19447 or equivalent ASTM B359 ASME SB359;

Material: red Cooper T2/TP2, Cooper magnesium iron alloy BFe 10-1-1, miscellaneous brass Hsn 701, HA177-2, etc.

Outer diameter (OD): 7-16mm

Tube length: up to 16000mm

Fin height: 1.2mm ~2.77mm

Fin thickness: about 0.3mm

Rotation angle: 0-28°

Fin pitch: 30 FPI/28 FPI/26 FPI/36 FPI/43 FPI

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

Data sheet of Inner Grooved Low Finned Tubes

| Plain tube (mm) | Finned section dimensions (mm) | Ratio | De | |||

| D×t | Tp | dd | dr | di | η | mm |

| 19×2 | 0.8 | 18.8 | 17 | 134 | 2.8 | 17.9 |

| 19×2 | 1 | 18.8 | 16.8 | 13.4 | 2.5 | 17.8 |

| 19×2 | 1.25 | 18.8 | 16.6 | 13 | 2.2 | 17.8 |

| 19×2 | 1.5 | 18.8 | 16.6 | 13 | 2 | 17.7 |

| 19×2 | 2 | 18.8 | 16.4 | 13 | 1.7 | 17.5 |

| 25×2.5 | 0.8 | 24.8 | 23 | 18.8 | 2.8 | 23.9 |

| 25×2.5 | 1 | 24.8 | 22.6 | 18.8 | 2.75 | 23.7 |

| 25×2.5 | 1.25 | 24.8 | 22.3 | 18 | 2.5 | 23.6 |

| 25×2.5 | 1.5 | 24.8 | 22.3 | 18 | 2.2 | 23.5 |

| 25×2.5 | 2 | 24.8 | 22 | 18 | 1.8 | 23.4 |

| 25×2.5 | 2.5 | 24.8 | 22 | 18 | 1.6 | 23.3 |

| D——Outside diameter of plain end section Dof—-Diameter of top fins Dr—–Root diameter of finned section Di—–Inside diameter of finned section T——Wall thickness of plain end section Tp—–Fin pitch De—-Equivalent diameter of finned tube L——Plain tube end length | ||||||

| Please email us for more information. | ||||||

We can provide monolithic low finned tubes with no fin section clearance (min. 5mm) in the middle of the core tube, or bent to the designed bend radius.

Example:

Manufacturing Process:

Inner Grooved Low Finned Tubes are ordinary heat exchange tubes that are rolled to form threads on the inner surface, and the fins are rolled out from the outer wall of the plain tube through rollers. A high-efficiency heat exchange tube type with tubes and fins in the same tube.

Delivery conditions:

The tube ends are square cut, free of burrs, dry and blown clean on the inside and varnished on the outside.

Put desiccant in each package for continental shipping.

Quality Test:

The integral low fin tube quality is assured by hydrostatic or pneumatic tests, eddy current tests & MARCO tests in order to verify design specifications.

Acceptance ceritia:

WOLVERINE / HPT / GEWA-K & GEWA-KS

Features of Inner Grooved Low Finned Tubes

⑴ low processing cost;

⑵ wide application. It has a strengthening effect on the evaporation, condensation, gaseous heat transfer and liquid heat transfer of the shell-side medium;

3. The inner surface area is 1.5-2 times that of ordinary pipes, and the thermal conductivity is 1.5-2.4 times that of ordinary pipes of the same size. The flow resistance is only increased by 3%-5%, saving 20%-35% of energy, reducing

Air conditioner weight 10%-25%.

Packaging: Iron frame packing box

Application

Inner Grooved Low Finned Tubes are mainly used in petrochemical, power, paper, tobacco, building heating and other industries, such as air coolers, air heaters, food industry vegetable protein powder, starch and other air heater spray drying systems.

As long as the medium on the shell side is relatively clean, free from corrosion and scaling, low-thread finned tubes can be used as heat exchange elements to form a low-thread finned-tube type high-efficiency heat exchanger.

The working temperature is up to 250 degrees.

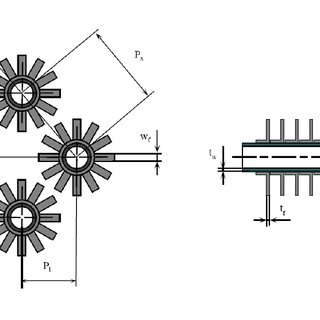

Longitudinal I/L or U-finned tubes are produced from resistance welded fins along the length of the tube. The fins first form a U-shaped channel so that each leg of the U forms a fin. Channels are cut to the appropriate length, then oriented and resistance welded in place along the length of the tube. The channels are welded in pairs, diametrically opposed, so the number of fins specified must be a multiple of 4.

For a given tube or tube size, the desired heat transfer surface area per unit length of tube can be obtained by specifying the appropriate fin height and number of fins. The number of large fins depends on the outer diameter of the tube – larger OD tubes can accommodate more fins.

Longitudinal Finned Tube For Heat Exchangers Quick Details:

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

4. Titanium: B338 Gr 2

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Fin type: U-fin, perforated, twisted…

Tube Outer Diameter: Min. 19mm.

Tube length: up to 18 meters.

Number of fins: 2/4/8/16/18/32/36 pieces per row

Number of fins: 16/20/24/32/40

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

The case of Longitudinal Finned Tube For Heat Exchangers

We can customize Longitudinal Finned Tube for heat exchanger according to your drawings

Example:

Manufacturing Process:

Longitudinal I/L or U-shaped fins are welded to the core light pipe by resistance welding or filler metal welding (spot welding).

Longitudinal Finned Tube with two different materials

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

| Carbon Steel Tubes | A179, A192, SA210 Gr A1/C, A106 Gr B, A333 Gr3 Gr6 Gr8, A334 Gr3 Gr6 Gr8, 09CrCuSb, DIN 17175 St35.8 St45.8, EN 10216 P195 P235 P265, GB/T3087 Gr10 Gr20, GB/T5310 20G 20MnG, |

| Alloy Steel Tubes | A209 T1 T1a,A213 T2 T5 T9 T11 T12 T22 T91,A335 P2 P5 P9 P11 P12 P22 P91,EN 10216-2 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4 |

| Stainless Steel Tubes | TP304/304L, TP316/TP316L TP310/310S TP347/TP347H |

| Copper Tubes | UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10 |

| Titanium Tubes | B338 Gr 2 |

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Quality Control

Inspection and Tests Performed

Chemical Composition inspection,

Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test), S

surface and Dimension Test,

No-destructive Test,

Hydrostatic Test.

Delivery conditions

The tube ends are square cut without burrs, the inside is dry and blown clean, and the ends of the L-shaped tension wound finned tube are coated with varnish on the outside.

Features of Longitudinal Finned Tube

①Increase heat transfer efficiency in effective space.

② Reduce the installation space of the required heat transfer surface

③ Reduce equipment cost and have high operational reliability.

④ Reduce the pressure drop on the pipe side and reduce the operating cost.

⑤ Improve the rigidity of the steel pipe and improve the seismic performance of the steel pipe.

⑥Enhancing heat transfer, reducing flow resistance and metal consumption

Application

Longitudinal fin construction is commonly used in shell and tube applications.

The choice of longitudinal finned tube versus helical finned tube seems to depend primarily on geometrical factors. For example, some heater structures consist of finned tubes inserted within other tubes – longitudinal finned tubes are the obvious choice for this type of application. In other cases, users prefer a longitudinal finned tube installation, where the tubes will be in a vertical orientation – the finned orientation facilitates fluid drainage on one side of the finned tubes. Longitudinal finned structures are commonly used in shell and tube applications, such as in double-tube and multi-tube heat exchangers, where the longitudinally finned tubes are telescoping within the holes of a larger tube shell. Heat is transferred between the fluid flowing through the finned tube holes and the fluid flowing through the housing holes. Fluid flowing through the housing holes is forced to flow between the longitudinal fins. In this case, the helical fins would block the flow of fluid rather than allow fluid to flow between the fins.

Quality Control

Delivery conditions

Acceptance Criteria

Features of Aluminum Finned Tube

Application

Copper-aluminum composite finned tube is a bimetallic finned tube in which copper and aluminum composite tubes are composited and then rolled into fins, which overcomes the defect that aluminum and other metals cannot be welded. It has the characteristics of tight bonding, small thermal resistance, good heat transfer performance, high strength, small flow loss, strong corrosion resistance, not easy to deform under long-term hot and cold working conditions, and long working life.

The copper-aluminum composite finned tube is an integrally rolled fin with smooth, burr-free, wrinkle-free and easy to clean. It is easy to remove condensed water on the outer surface of the fin during wet cooling in heating and air-conditioning projects. Not easy to dust and scale.

Copper aluminum composite finned tube Quick Details:

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

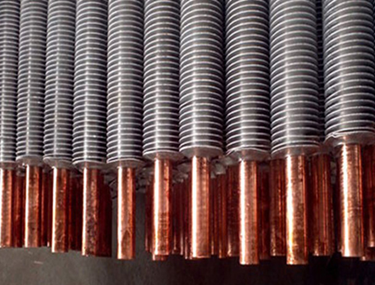

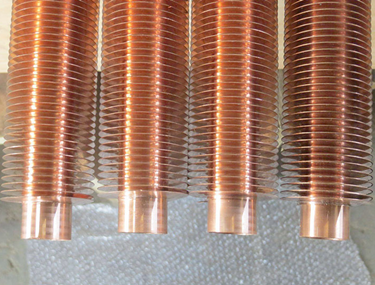

The case of Copper Aluminum Composite Finned Tube

We can customize Longitudinal Finned Tube for heat exchanger according to your drawings

Manufacturing Process:

Copper-aluminum composite finned tube is a bimetallic finned tube in which copper and aluminum composite tubes are composited and then rolled into fins.

Quality Control

Inspection and Tests Performed

Chemical Composition inspection,

Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test), S

surface and Dimension Test,

No-destructive Test,

Hydrostatic Test.

Delivery conditions

The tube ends are square cut without burrs, the inside is dry and blown clean, and the ends of the L-shaped tension wound finned tube are coated with varnish on the outside.

Acceptance Criteria

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

Features of Copper-aluminum composite finned tube

(1) Light weight.

(2) Good heat transfer performance.

(3) Small air resistance.

(4) Low touch thermal resistance.

(5) The heat dissipation area is large.

(6) Long service life.

(7) The steel-aluminum composite finned tube is not easy to produce dust and scaling.

The copper-aluminum composite finned tube has the characteristics of tight bonding, low thermal resistance, good heat transfer performance, high strength, small flow loss, and strong corrosion resistance. All rolled fins are lubricated, wrinkle free and easy to clean. When wet cooling is performed in heating and air conditioning projects, the condensed water on the outer surface of the fins is easily removed, and it is not easy to accumulate dust and scale in heat exchange occasions such as dry heating.

Application

Copper-aluminum composite finned tubes are widely used in water-cooled air heat exchangers and high-temperature water radiators in the petroleum and chemical industries.

Copper finned tube refers to a single-metal composite finned tube made of high-quality red copper tube as the base tube. Through a special winding machine, the high-quality red copper tape is tightly and evenly wound on the outer surface of the base tube, and then tinned as a whole. Working temperature of Copper Finned Tube:-10℃-+160℃ₒ

Copper Finned Tube For Heat Exchanger Quick Details:

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

The case of Copper Finned Tube

We can customize Copper Finned Tube according to your drawings

Manufacturing Process:

Copper Finned Tube refers to a single-metal composite finned tube made of high-quality red copper tube as the base tube, through a special winding machine, the high-quality red copper tape is tightly and evenly wound on the outer surface of the base tube, and then tinned as a whole.

Quality Control

Inspection and Tests Performed

Chemical Composition inspection,

Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test), S

surface and Dimension Test,

No-destructive Test,

Hydrostatic Test.

Delivery conditions

The tube ends are square cut without burrs, the inside is dry and blown clean, and the ends of the L-shaped tension wound finned tube are coated with varnish on the outside.

Features of Copper Finned Tube

(1) No contact thermal resistance,

(2) Good heat transfer performance,

(2) High strength,

(3) Heat resistance and mechanical vibration, good thermal expansion performance, and a considerable extended heat exchange surface.

Application

Aluminum Finned Tube is widely used in industrial refrigeration radiators, air coolers, working temperature: -10℃-+160℃.