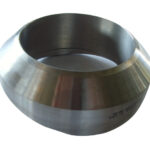

Forged Pipe Fittings

Forged pipe fittings are available according to ASME B16.11, MSS-SP-79\83\95\97, and BS3799 standards and specifications. These fittings are useful in connecting nominal bore pipes. They are of carbon steel A105 and stainless steel SS316 material. The size of these fittings varies from 1/8” to 4 inches. These fittings received its name due to the manufacturing process, which involves forging. During the manufacturing of these fittings, the raw material, i.e., steel alloy or carbon alloy, is subjected to temperature and formed into a customizable shape.

Forged Pipe Fittings are available in socket weld pipe fitting and threaded pipe fitting form. These pipe fittings are made of A105 carbon steel, stainless steel, and even nickel alloy. All these raw materials work well for the formation of pipe fittings. Forged pipe fittings are heavier, thick, and intended to use in heavier applications. These pipe fittings show 2000#, 3000#, 6000#, and 9000# pressure classes.

Threaded Forged Pipe Fittings is one of the ranges of pipe fittings that are generally used to install and connect the bores of two or more tubes or pipe fittings. Therefore these threaded fittings are screwed mutually to join or connect the piping systems. These fittings are helped in regulating, changing, and measuring the way of the fluids. Moreover, these are closes or seal the pipes to avoid any leakage.

These fittings are tapering groves cut into the ends of the run pipe and are easily accumulate without any other permanent means of attachment and welding. The fittings are designed in both male and female fittings. The male threaded fittings pose external threads are screwed inside the pipe end .while the female fittings ensure internal thread and they are either screwed inside or outside of the pipe end.

The fittings are designed from various materials that offer superior resistance properties. Moreover, it exhibits excellent formability, durability, and workability. These fittings are anti corrosive and posses high tensile strength. Furthermore, it demonstrates superior resistance to pitting, crevice and stress corrosion cracking at the hostile environment. These fittings acclaimed superior dimensional accuracy and require low maintenance.

Standard specifications of Threaded Forged Pipe Fittings:

Dimensions : MSS SP-95, BS 3799, ASME 16.11, 83, MSS SP-79, 97, 95

Pressure class : 2000LBS, 3000 and 6000 LBS

Forms: Elbow, Tee, Union, Plug, Cross, Nipples, Bushing, Cap, Coupling, etc.

Size : 1/8”NB-4” NB

Features:

The screwed-threaded-fittings have features such as-

• Anti-corrosive with respect to the environment

• It has the high tensile strength

• It is stress corrosion cracking/crevice corrosive/pitting/oxidation/corrosion resistance

• It has acclaimed dimensional accuracy

Materials:

| Stainless Steel | ASTM /ASME A/SA 213 / 249 / 269 / 312 / 358 CL. I to V – 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316TI , 316H , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H , 904L . |

| Duplex Steel | ASTM/ASME A/SA 789, 790 – UNS NO S 31803, S 32205, S 32550, S 32750, S 32760. |

| Carbon Steel | ASTM A106 Gr. A, B & C API 5L Gr. A / B, X42 ,X52 ,X60 ASTM A 53 Gr. A/B |

| Alloys Steel | ASTM /ASME A/SA 213 / 335 / 691 – P5,P9,P11,P12,P22,P91 |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

Socket Weld Forged Pipe Fittings are a type of pipe fittings that are joined to the pipe into a blank area of fittings. These fittings are widely used in small pipe diameters mainly for the piping system whose nominal diameter is NPS 2 or smaller than that. To join the pipe with the valve or make any connection between two pipes socket weld fittings are used. It is a great choice for a wide range of application as it offers the best performance and reduces the leakage problem.

These fittings have great structural strength and have lower fatigue resistance because of the use of fillet welds as well as abrupt fitting geometry; still, they are considered a great choice for mechanical joining method. Socket weld fittings are basically a family of high-pressure fittings that are used in numerous industrial processes.

Usage of socket weld fittings

Socket weld pipe fittings normally used in high pressure pipeline systems in different industries as below:

• Oil and Gas, petrochemicals.

• Medical science.

• Power stations of electric or nuclear.

• Environment control.

• Aerospace constructions.

• Fire protection systems.

• Mining slurry.

• Shipbuilding.

Forged Fittings Types | Socket Weld Fittings: Elbow 90 Deg, Cross, Tee, Elbow 45 Deg, Coupling, Half Coupling & End Cap. |

Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120,SCH140, SCH160, XXS |

Size | 1/8″NB to 24″NB & 1/4″OD TO 24″OD AND 6.35mm to 254mm OD Thickness: 0.6mm to 20mm |

Materials:

| Stainless Steel | ASTM /ASME A/SA 213 / 249 / 269 / 312 / 358 CL. I to V – 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316TI , 316H , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H , 904L . |

| Duplex Steel | ASTM/ASME A/SA 789, 790 – UNS NO S 31803, S 32205, S 32550, S 32750, S 32760. |

| Carbon Steel | ASTM A106 Gr. A, B & C API 5L Gr. A / B, X42 ,X52 ,X60 ASTM A 53 Gr. A/B |

| Alloys Steel | ASTM /ASME A/SA 213 / 335 / 691 – P5,P9,P11,P12,P22,P91 |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |