Oil Country Tubular Goods

OCTG is the abbreviation of Oil Country Tubular Goods, it mainly refers to the piping products that applied in the oil and gas production (drilling activities). OCTG pipe normally is manufactured based on API or related standard specifications. It also could be taken as a collective name of Drill pipe, Steel Casing Pipe and Tubing pipe, Couplings, Connections and Accessories, used in petroleum industries that onshore and offshore.

According to the API (American Petroleum Institute) standardized specifications, through the control on the chemical properties and adopts different heat treatment, OCTG pipe is classified into different performances material more than ten grades.

Drilling of oil and gas wells and transportation of oil and gas, main products include:casing,tubing,drill pipe,drill collar, heavy weight drill pipe,slotted pipe, line pipe, coupling and pup joint.

Casing is a large-diameter pipe that serves as the structural retainer for the walls of oil and gas wells, or well bore.It is inserted into a well bore and cemented in place to protect both subsurface formations and the well bore from collapsing and to allow drilling fluid to circulate and extraction to take place. Steel Casing Pipes have smooth wall & minimum yield strength of 35,000 psi.

Well Casing serves as well sidewall. Standards and Technical Conditions for Supply:API Spec 5CT ISO13680 Grade: J55, K55, N80-1,N80-Q, L80-1, L80-9Cr,L80-13Cr,C95, P110. Tread types: NUE, EUE, VAM, STC, LTC, BTC, special clearance, XC,VAM TOP,NEW VAM.

Oil Casing Pipe: Casings are used for fixing the well wall or down hole, which have wide diameters, can be divided into conductor casings, technical casings and Oil casings.

Uses: Well Casing serves as well sidewall.

Standards and Technical Conditions for Supply:API Spec 5CT

Grade of pipe casing: J55, K55, N80-1,N80-Q, L80-1, L80-9Cr,L80-13Cr,C95, P110.

Tread types of pipe casing : STC, LTC, BTC, special clearance, XC,VAM TOP,NEW VAM.

Dimension: OD: 114.3-508mm WT: 5.21-16.13mm

Process: ERW and Seamless

Standard: API 5CT

Certificate: Tubing: LTC, STC, BTC, VAM.Tubing: NUE, EUE.

Out Diameter: Casing: OD 4 1/2″- 20″ (114.3mm-508mm)

Tubing: OD 2 3/8″ – 4 1/2″ (60.3mm-114.30mm)

Wall Thickness: 0. 205″- 0.635″

Length: R1(4.88mtr-7.62mtr), R2(7.62mtr-10.36mtr), R3(10.36mtr or longer)

Steel Grade: H-40, J55, K-55, N-80, C-75, L-80, C-90, T-95, Q-125

Surface: Corrosion proofing water based paint

End: Beveled, Square cut. And pipe protection cap especially for casing and tubing.

Heat treatment: Normalized, Quencher+Temper

Tubing: Tubing is pipe used for the transportation of crude oil and natural gas from an oil or gas layer to the surface after drilling is complete. It is made to withstand the pressure generated from the extraction process. Tubing is manufactured in the same way as casing, except that an additional process known as “upsetting” is applied to thicken the pipes.

Drill pipe includes pipe body and tool joints(box and pin) welded together, used to connect drilling rig surface equipment and bottom equipment or bottom hole equipment. Drill pipe can bear heavy internal and external pressure, and twist, bend and vibration which can be used more than one time during oil or gas production.

Drill pipes are steel tubulars fitted with threaded ends called tool joints, which are commonly used in tension in the top part of the drill string to pump fluid and transmit torque to the bit.

Standard: Drill pipe

Grade: E75, X95, G105, S135 .

The wear-resistant belt of tool joint: Arnco 100XT, 200XT, 300XT, 400XT

Internal coating drill pipe: TK34, DPC, TC2000, TC3000

Usage: Mine blasting, water well drilling, geothermal wells drilling, fore poling, coal and nonferrous metal mining projects, etc.

Drill collar as one component of a drill string is extremely industrial tubulars used to drill into ground to provides weight on bit for drilling. It is used to conjunction with drill pipe. There are slick and spiral grooved types mainly. Our manufacturing process is certified to API spec 7-1. The drill collar is made of AISI 4145 H or 4145 H Modified alloy steel. Bores are trepanned from one direction with no mismatch. All drill collars are heat-treated with hardness within 285 to 341 BHN, which are guaranteed one inch below the surface of the pipe.

Non-magnetic drill collars offer strength and hardness while preventing magnetic interference that may impair accuracy of magnetic surveys. It is manufactured from special steel material with low permeability, high mechanical properties and superior resistance to corrosion cracking.

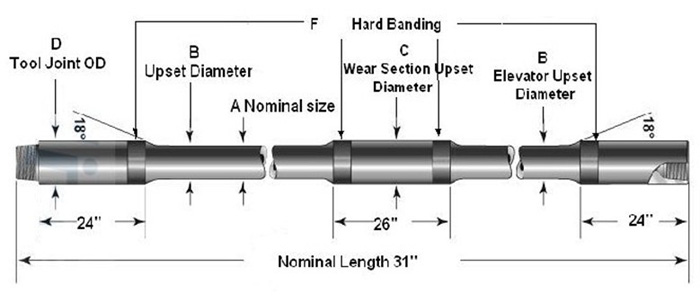

Integral heavy weight drill pipe is the transition zone between drill collar and drill pipe. It can not only reduce stress-formation in the connection of drill collar and drill pipe, but also reduce the wear on OD.

Integral heavy weight drill pipe is made from one piece of AISI 4145H solid bar, fully heat treated, all physical properties conform to API spec7 latest edition.

HWDP’s wear resistance hard banding is standard on tool joints connections and central upset. The types of hard banding include Arnco 100XT and100XT. All threads are phosphated, copperized or cold worked. All connections are equipped with pressed steel thread protectors. All theads are machined with CNC lathes –Double-shoudered and special threads.

Standard: API 5L

Application: For gas, water, transportation in Petroleum and natural gas industries

Tolerance on Dimensions

Standard | Out Diameter | Wall Thickness | |

API 5L | Tolerance | Tolerance | |

D<60.3 | +0.41mm, -0.80mm | +15.0%, -12.5% | |

D≥60.3 | +0.75%D, -0.75%D | +15.0%, -12.5% | |

Standard

Standard | Grade | Chemical Components (%) | Mechanical Properties |

| ||||||

C | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) |

| |||

API 5L PSL1 | A | 0.22 | – | 0.90 | 0.030 | 0.030 | ≥331 | ≥207 |

| |

B | 0.28 | – | 1.20 | 0.030 | 0.030 | ≥414 | ≥241 |

| ||

X42 | 0.28 | – | 1.30 | 0.030 | 0.030 | ≥414 | ≥290 |

| ||

X46 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥434 | ≥317 |

| ||

X52 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥455 | ≥359 |

| ||

X56 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥490 | ≥386 |

| ||

X60 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥517 | ≥448 |

| ||

X65 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥531 | ≥448 |

| ||

X70 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥565 | ≥483 |

| ||

API 5L PSL2 | B | 0.24 | – | 1.20 | 0.025 | 0.015 | ≥414 | ≥241 |

| |

X42 | 0.24 | – | 1.30 | 0.025 | 0.015 | ≥414 | ≥290 |

| ||

X46 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥434 | ≥317 |

| ||

X52 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥455 | ≥359 |

| ||

X56 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥490 | ≥386 |

| ||

X60 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥517 | ≥414 |

| ||

X65 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥531 | ≥448 |

| ||

X70 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥565 | ≥483 |

| ||

X80 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥621 | ≥552 |

| ||

Casing coupling is a short pipe applied in connecting two casing pipes which have threads. The pipe coupling has internal threads machined to match the external thread of the long joints of casing. The two joints of casing pipes are screwed into opposite ends of the casing coupling. Through their strength can be normally made of the same grade of steel as the casing. All casing couplings are manufactured in accordance with API 5CT specification of the latest edition.

Properties of Casing Couplings:

♦ The material of casing couplings is H40, J55, K55, M65, N80-1, N80Q, L80, C95, T95 and P110 grade steel with high quality and good performance;

♦ The outer diameter ranges from 127mm to 365.12 mm;

♦ The casing couplings thread patterns include short round thread, long round thread and buttress thread.

Tubing coupling is a kind of drilling tool available in oil field. Tubing couplings are mainly used in connecting oil pipes. This type of pipe coupling has handled the problem that the existing couplings tend to crack because of stress concentration. The oil pipe ends and the inner wall of the tubing coupling are connected by threads. And the oil pipes and the ends of the tubing coupling have the same type of threads. It is not easy to crack for this type of connection and the connection effect is good. The tubing coupling can avoid the oil well string dropout accident effectively.

Properties of Tubing Coupling:

♦ The material of tubing couplings is H40, J55, N80-1, N80Q, L80, C90, T95 and P110 grade steel with high quality and good performance;

♦ It is mainly used to connect two oil pipes;

♦ The tubing coupling thread patterns include non-upset thread and upset thread;

♦ The outer diameter of tubing coupling ranges from 55.88 mm to 141.3 mm;

API Tubing Coupling

| Specification | |

| Size (Pipe OD) (in) | 1.900, 2-3/8, 2-7/8, 3-1/2, 4, 4-1/2 |

| Upset | Non UpsetExternal Upset |

| Grade | J-55, C-75, L-80, N-80, C-95, P-110 |

| Option | Electro-zinc plated Phosphorised |

API Casing Coupling

| Specification | |

| Size (Pipe OD) (in) | 4-1/2, 5, 5-1/2, 6-5/8, 7, 7-5/8, 8-5/8, 9-5/8, 10-3/4, 11-3/4, 13-3/8, 16, 18-5/8, 20 |

| Threading | Short Round-Thread Casing (STC)Long Round-Thread Casing (LC)Buttress Thread Casing (BC) |

| Grade | H-40, J-55, K-55, C-75, L-80, N-80, C-95, AS-95, P-110, L80-13CR |

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

They are available in standard lengths of 5’, 10’, 15’ and 20’ with other configurations upon request.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

We can offers a wide range drill string products and accessories with standard API or proprietary high performance

connections to meet the most demanding drilling requirements.

| Tubing Pup Joint Specifications | |

| Outside Diameter | 1.05 ~ 4-1/2 in (26.67 ~ 114.3 mm) nominal size OD |

| Weight | Standard or Heavy Wall |

| Length | 2, 3, 4, 5, 6, 8, 10, 12 ft (with other lengths available upon request) |

| Grade | H40, J55, L80, N80/Q, C90, T95, P110 |

| Connection | EUE, NUE |

| Standard | API 5CT, API 5B |

| Casing Pup Joint Specifications | |

| Outside Diameter | 4-1/2 ~ 20 in (114.3 ~ 508 mm) nominal size OD |

| Weight | Standard or Heavy Wall |

| Length | 2, 3, 4, 5, 6, 8, 10, 12, 14, 16, 18, 20 ft (with other lengths available upon request) |

| Grade | H40, J55, K55, L80, N80/Q, C90, T95, P110, Q125 |

| Connection | BTC, STC, LTC |

| Standard | API 5CT, API 5B |