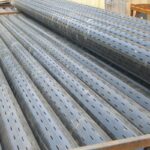

Slotted Casing Pipe

Slotted Casing Pipe is used in oil exploration can prevent 99% sand, decrease 80% of oil well heavy maintenance, as well increase the strength of the oil well, integrality and stability of keeping sand off. Meanwhile, the laser incision tech can make the slot be smooth and precision. The structure of slotted casing pipe is sample, but it works highly efficient.

Slotted tube processing is on high strength steel body with cold or hot working methods, cutting out hundreds of thousands of longitudinal cracks, cracks commonly used specifications for: seam width 0.15 3 mm, even more wide, gap length 50-200 mm.Cross section types are: rectangular, ladder shaped, specific and various, also has a circular groove screen, aperture diameter specifications range 5-20 mm in meters.Slotted sieve tube hole seam cutting quality mainly depends on the precision of seam width, hole seam cross-section shape neat degree, on the edge of the hole seam smoothness and the degree of corrosion resistance of hole seam.

Straight Slots – Slots are cut with equal width through the wall of the pipe both ID and OD. Specified where sand grain bridging at the slot is not of major importance, straight slots are more wear-resistant than seamed keystone slots and are less costly to produce. Common applications of Straight cut slots are for Cold Production and CBM horizontal wells in addition to SAGD injector wells.

Seamed Keystone Slots – -are milled wider on the pipe interior and are self cleaning to help prevent plugging. Narrow at the liner surface and increasing in width at the interior, they let sand that does enter pass easily through the slots without plugging.

API Casing pipe | ID | Length | Slot Length | Slot No. | Slot width | Slot | Valid Filter | Max. Strength | ||

Spec mm | Thickness | Per Weight | ||||||||

60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

73.02 | 5.5 | 9.15 | 62 | 240 | 57.6 | 688.55 | ||||

88.9 | 6.5 | 13.22 | 75.9 | 280 | 67.2 | 995.1 | ||||

101.6 | 6.5 | 15.22 | 88.6 | 300 | 72 | 1151.2 | ||||

114.3 | 7 | 18.47 | 100.3 | 10 | 320 | 76.8 | 1400.4 | |||

127 | 7.52 | 22.13 | 112 | 340 | 81.6 | 1673.8 | ||||

139.7 | 7.72 | 25.11 | 124.3 | 360 | 86.4 | 1900.2 | ||||

9.17 | 29.48 | 121.4 | 360 | 86.4 | 2232.4 | |||||

168.3 | 8.94 | 35.09 | 150.4 | 400 | 96 | 2672.95 | ||||

177.8 | 8.05 | 33.68 | 161.7 | 440 | 105.6 | 2559.2 | ||||

9.19 | 38.19 | 159.4 | 440 | 105.6 | 2940.7 | |||||

Sreen pipe dimension (in) | OD(mm) | Wall thickness(mm) | ID (mm) | Stitch number of each circle | Slot width(mm) | Slot length (mm) | Length(mm) |

2-3/8″ | 60.3 | 4.83 | 50.64 | 12~18 | 0.2~0.8 | 45~100 | 1000~12000 |

2-7/8″ | 73 | 5.51 | 61.98 | 20~24 | 45~100 | ||

3-1/2″ | 88.9 | 6.45 | 76 | 24~28 | 45~100 | ||

4″ | 101.6 | 6.65 | 88.29 | 24~30 | 45~100 | ||

4-1/2″ | 114.3 | 5.69 | 102.92 | 24~30 | 45~100 | ||

6.35 | 101.6 | 45~100 | |||||

7.37 | 99.57 | 45~100 | |||||

8.56 | 97.18 | 45~100 | |||||

5″ | 127 | 5.59 | 115.82 | 28~36 | 0.25~0.8 | 45~100 | |

6.43 | 114.15 | 45~100 | |||||

7.52 | 111.96 | 45~100 | |||||

9.19 | 108.61 | 45~100 | |||||

5-1/2″ | 139.7 | 6.2 | 127.3 | 30~38 | 45~100 | ||

6.99 | 125.73 | 45~100 | |||||

7.72 | 124.26 | 45~100 | |||||

9.17 | 121.36 | 45~100 | |||||

10.54 | 118.62 | 45~100 | |||||

7″ | 177.8 | 6.91 | 163.98 | 36~50 | 45~100 | ||

8.05 | 161.7 | 45~100 | |||||

9.19 | 159.41 | 45~100 | |||||

10.36 | 157.07 | 45~100 |

- Slotted casing pipe are used J55/K55/N80 casing, with high overall strength, not so easy to deformation.

- The edge of the slot is vertical, smooth, without burrs, and the slot is uniformity.

- The perforated pipe is suitable for sandy well, which the diameter of the sand greater than 0.3mm.

- The slot can be longitudinal and transverse, the section of the slot can be parallel and trapezoidal types, with a wide open area.

- Slotted screen pipe has a big inner diameter.